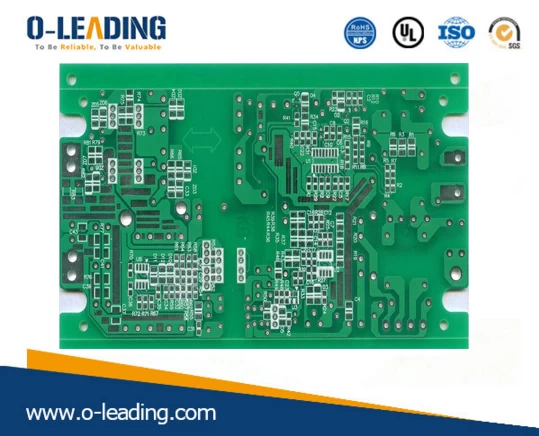

Why most PCBs are green

o-leading

o-leading.com

2018-03-21 11:15:14

In addition to the green oil, there is a difference between the commonly used blue oil, butter, black oil, black matt oil, purple oil, red oil, green matt, green sun, etc. I think the main problem is cost. Green ink is the largest ink manufacturer in China, the general price is about 1KG 80, while the price of the same type of green sun and green matte ink between 150 - 250 of course there are cheaper blue matte ink , The price is about 1KG in 60, the question can mainly know, now the high-accuracy PCB board still needs to carry on the alignment operation manually, the other ink color is too easy to cause the flaw to the manual operation. (Alignment is a step of solder resist, which is to wash away the unnecessary solder mask by potion. The accuracy of the washout needs manual alignment operation to complete, and the details are not elaborated.) In this way, the rework is much better. It is a big test for manufacturers.

In summary, the cost is the biggest reason. If you want more interesting information about PCBs, please click the link hina pcb manufacturer.

In summary, the cost is the biggest reason. If you want more interesting information about PCBs, please click the link hina pcb manufacturer.