Which areas of the PCBA board cannot be coated with three anti-paints?

In fact, this is not very specific in the industry, and is related to the actual needs of users. Generally, connectors, switches, heat sinks, gold fingers, positioning holes, etc. are shielded before they are applied. According to the experience, the following areas cannot be coated with three anti-paint.

The requirements for most products when applying three anti-paints are as follows:

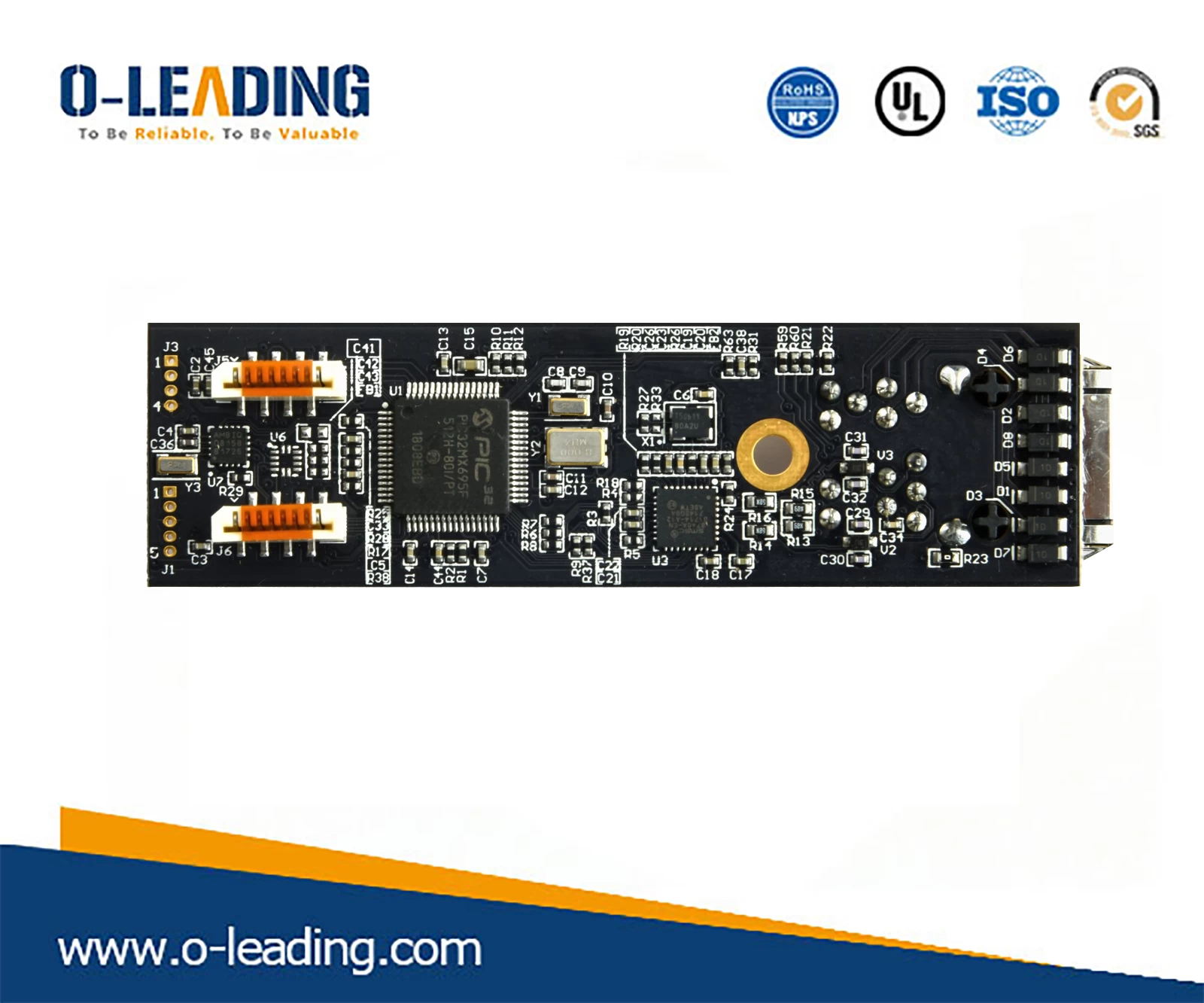

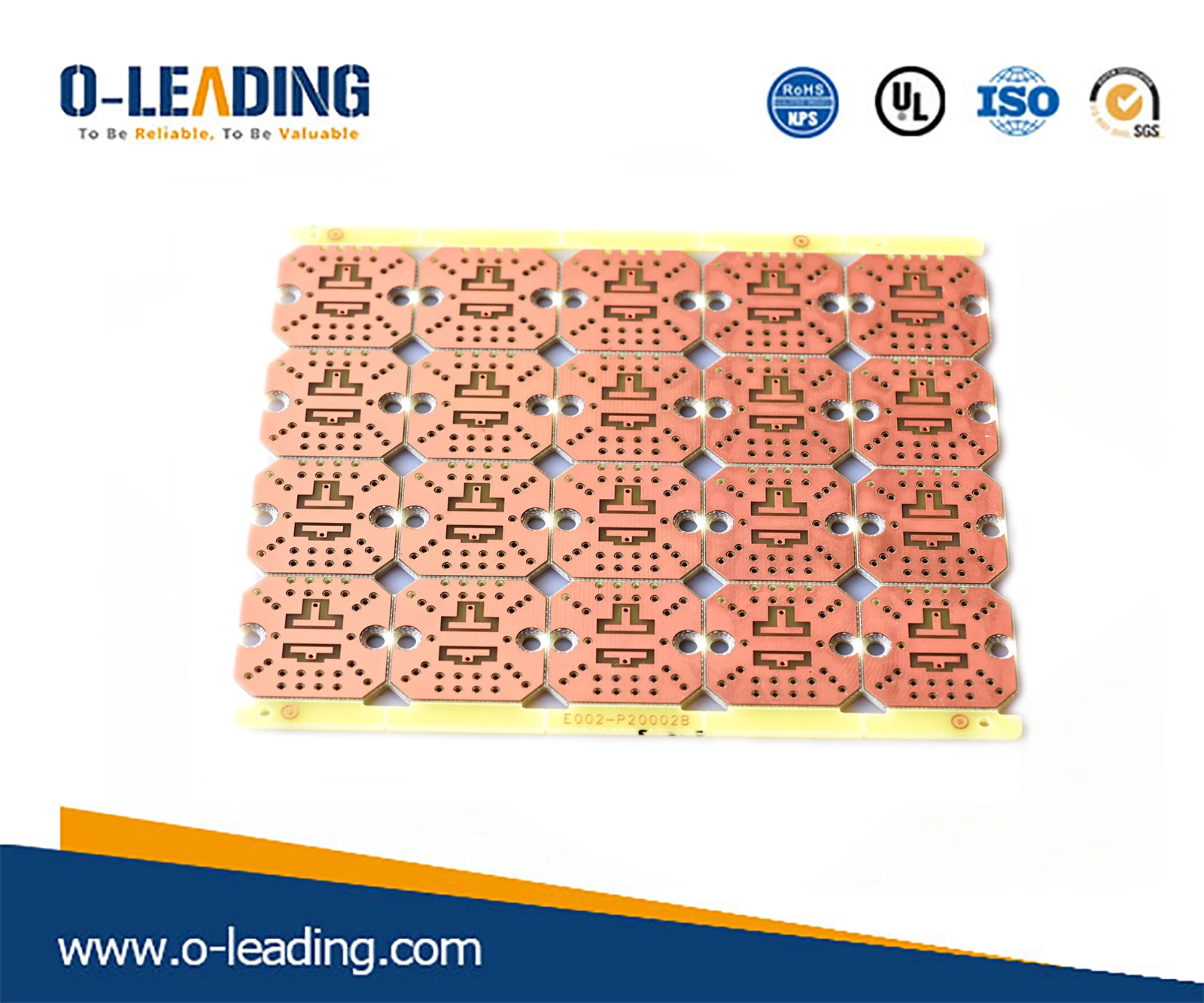

GOLDEN FINGER BOARD supplier.

Areas that cannot be coated:

1. Areas that require electrical connections, such as gold pads, gold fingers, metal through holes, test holes, etc.;

2. Battery and battery holder;

3. Connector;

4. Fuse and outer casing;

5. Heat sink;

6. Jumper;

7. The lens of the optical device;

8. Potentiometer;

9. Sensor;

10. A switch without a seal;

11. Other areas that will be affected by the coating or performance.

For example, inductive components, after applying three anti-paints, may affect electrical properties, must be tested beforehand.

Area that must be coated:

Except for the above mentioned areas, all other solder joints, component legs, and component conductor parts should be coated. Generally, the entire board is coated after protecting the components that must be shielded.