What processes does FPC flexible circuit board have? How to test?

The process of FPC soft board includes: exposure, PI etching, opening, electrical testing, punching, appearance inspection, performance testing, etc.

The production process of the FPC soft board is related to the performance of the FPC. After the production is completed, it needs to be tested to screen out the unqualified FPC soft board to ensure that the FPC maintains good performance in the application and plays the best role.

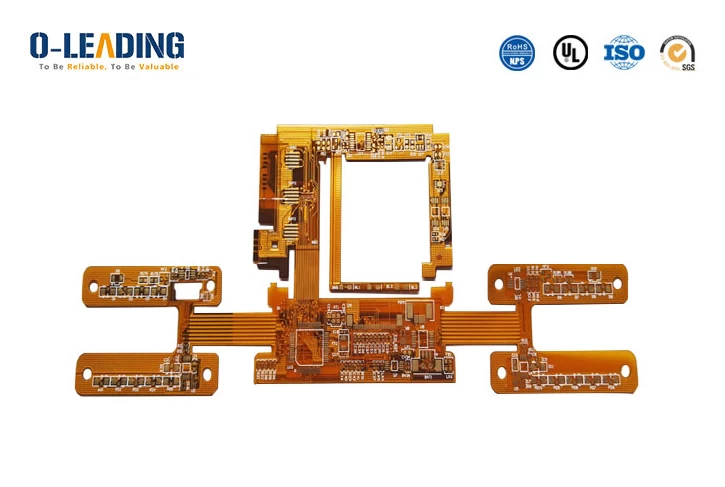

rigid-flexible pcb FPC for oled display control board

In the FPC soft board test, a large current shrapnel micro-needle module with conduction and connection function can be used to ensure the stability and efficiency of the FPC soft board test.

In the FPC soft board process, the exposure is to transfer the circuit pattern to the board through the action of the dry film. It is usually carried out by the photosensitive method. After the exposure is completed, the circuit of the FPC soft board is basically formed. The dry film can transfer the image. Protect the circuit during etching.

PI etching means that under certain temperature conditions, the etching solution is evenly sprayed on the surface of the copper foil through the nozzle, and the oxidation-reduction reaction occurs with the copper, and then the circuit is formed after the film removal treatment.

The purpose of the opening is to form the original conductor circuit and the interconnection circuit between the layers. The opening process is often used for the conduction connection of the upper and lower layers of the double-layer FPC.

professional rigid flexible pcb supplier for raspberry pi 4 abs case

In addition to service life, reliability and environmental performance, the performance indicators of FPC soft boards also include flexural resistance, flexural resistance, heat resistance, solvent resistance, solderability, peeling performance, etc. .

The folding resistance and flex resistance of the FPC soft board are related to the material and thickness of the copper foil, the type and thickness of the glue used for the substrate, and the material and thickness of the insulating substrate.

In the FPC soft board assembly process, the double-layer and multilayer FPC copper foils have good symmetry when they are laminated, and their flexural and bending resistance will be better.

Rigid Flexible high frequency pcb Manufacturing

The main application areas of FPC: including mobile phones, computers, PDAs, LCMs, digital cameras, automotive electronics, medical electronics, and consumer digital products such as hard disks, mobile storage, and printers.

O-Leading strives to be your one stop solution partner in EMS supply chain, We provide some of the most advanced PCB technology, including PCB design , PCB fabrication and PCB assembly (PCBA),HDI PCBs,multilayer PCBs, Rigid-Flexible PCBs.We can support from quick turn prototype to medium & mass Production.

We employ appropriate testing methods to make sure that everything is properly assembled according to your plans, and we inspect the finished product.