Technology | What is the difference between FPC and PCB?

Now electronic technology is getting more and more advanced, CPU can do 5nm process, circuit board can do dozens of layers, foldable screen is used in many mobile phones.

What is FPC

FPC: Flexible Printed Circuit, also known as "flexible board"

FPC is made of flexible substrates such as polyimide or polyester film. It has the advantages of high wiring density, light weight, thin thickness, flexibility, and high flexibility. It can withstand millions of dynamic bending without damaging the wires .

It can be moved and retracted arbitrarily according to the requirements of the space layout to realize three-dimensional assembly and achieve the effect of component assembly and wire connection integration. It has advantages that other types of circuit boards cannot match.

Application of FPC

There are many application scenarios of FPC, here are a few of them.

Mobile phone: Focus on the light weight and thin thickness of the flexible circuit board. It can effectively save the volume of the product, easily connect the battery, the microphone, and the keys.

Computer and LCD screen: use the integrated circuit configuration of the flexible circuit board and the thin thickness. Turn digital signals into pictures and present them through the LCD screen;

CD Walkman: Focusing on the three-dimensional space assembly characteristics and thin thickness of flexible circuit boards, turning a huge CD into a good companion to carry with you;

Disk drive: Whether hard disk or floppy disk, it relies heavily on the high softness of FPC and the ultra-thin thickness of 0.1mm to complete fast reading of data, whether it is PC or NOTEBOOK;

Third, the future development of FPC

Based on the vast market of China's FPC, large enterprises in Japan, the United States, and Taiwan countries and regions have already set up factories in China. By 2012, flexible circuit boards, like rigid circuit boards, have achieved great development.

However, if a new product follows the "start-development-climax-decline-elimination" rule, FPC is now in the area between the climax and decline. Before no product can replace the flexible board, the flexible board must continue to occupy market share , You must innovate. Only innovation can make it out of this strange circle.

So, what aspects will FPC continue to innovate in the future? There are four main aspects:

Thickness: The thickness of the FPC must be more flexible and thinner.

Folding resistance: FPC can be bent is an inherent characteristic of FPC. In the future, FPC's folding resistance must be stronger and must exceed 10,000 times. Of course, this requires a better substrate;

Price: At this stage, the price of FPC is much higher than that of PCB. If the price of FPC goes down, the market will definitely be much wider.

Process level: In order to meet various requirements, the FPC process must be upgraded, and the minimum aperture and minimum line width / space must meet higher requirements.

Therefore, the innovation, development, and upgrade of FPC from these four aspects can make it usher in the second spring!

What is a PCB

PCB: Printed Circuit Board, printed circuit board for short.

PCB is one of the important components of the electronics industry. Almost every kind of electronic equipment, from electronic watches, calculators, to computers, communication electronic equipment, military weapon systems, as long as there are electronic components such as integrated circuits, printed boards are used for electrical interconnection between them .

In the research of larger electronic products, the most basic success factor is the design, documentation, and manufacturing of the printed board of the product. The design and manufacturing quality of printed boards directly affect the quality and cost of the entire product, and even lead to the success or failure of commercial competition.

Five, the role of PCB

After the electronic equipment adopts printed boards, due to the consistency of similar printed boards, errors in manual wiring can be avoided, and automatic insertion or placement of electronic components, automatic soldering, and automatic detection can be achieved to ensure the quality of electronic equipment. , Improve labor productivity, reduce costs, and facilitate maintenance.

Development of PCB

Printed boards have evolved from single-layer to double-sided, multi-layer, and flexible, and still maintain their respective development trends. Due to the continuous development of high precision, high density and high reliability, and continuous reduction in size, cost, and performance, printed boards still maintain a strong vitality in the future development of electronic equipment.

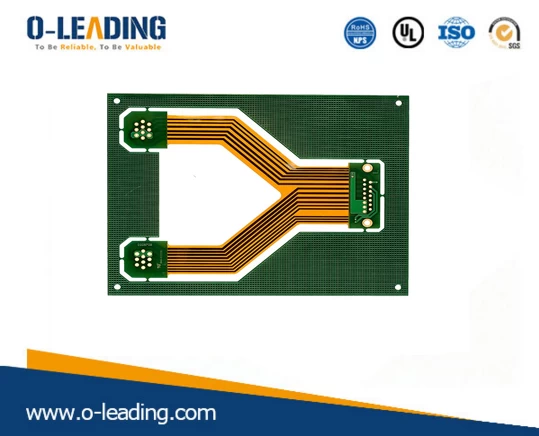

Double-layer Aluminum Based PCB

In recent years, the consumer electronics market, led by mobile electronic devices such as smart phones and tablet computers, has grown rapidly, and the trend toward smaller and thinner devices has become increasingly apparent. As a result, traditional PCBs have been unable to meet product requirements. For this reason, major manufacturers have begun to study new technologies to replace PCBs. Among them, FPC as the most popular technology is becoming the main connection of electronic equipme