SMT placement machine safety operation precautions

First, the board operation notes

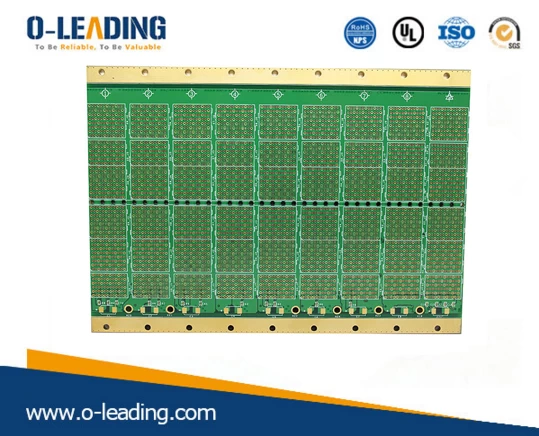

1. When the upper plate is on, the plate should be placed on the track parallel to the track and gently pushed forward. GOLDEN FINGER BOARD.

2. Make sure the board is placed on the belt of the track when the board is on the board. Don't let it go, causing the track to open. This causes the board to get stuck, which in the long run will also cause the track to become a bell mouth.

Second, the machine reported the handling of the alarm

1 If the on-site operator is familiar with the alarm information and knows the clear treatment measures and execution results, he can confirm the alarm fault information by himself. Refer to Table 1 "Key Equipment Alarm Information Processing Authority (Operator)". HIGH THERMAL CONDUCTIVITY HEAVY COPPER BOARD.

2 If the on-site operator is familiar with the alarm information and does not know the clear treatment measures and execution results, the alarm information cannot be confirmed and handled by himself. The alarm information should be protected and immediately notified to the line engineer or technician.

3 If the on-site operator is not familiar with the alarm information, the alarm information cannot be confirmed by himself. The alarm information should be protected and immediately notified to the line engineer or technician.

Third, the protection and processing of the fault site: divided into three cases

1 The device has abnormal performance during operation. Such as: abnormal sound, odor, motor overheating, etc., can take the shutdown method and notify the line engineer or technician to deal with; (Special attention: when stopping, first ensure that the product being produced has left the area where damage will occur after the shutdown, such as: reflux In the furnace, wave soldering high temperature zone) CERAMIC WAFER manufacturer china.

2 After the equipment fails in operation, there will be no further harm to the product or personnel. If the motor is stuck, the normal execution can not be performed, the moving parts are damaged or impacted, the pressure is abnormal, and the computer is dead, the on-site operator should stop all operations related to the equipment and notify the line engineer or technician immediately after the scene is protected. .

3 A malfunction that may cause further damage to the product or person after the device fails during operation. Such as: cleaning machine card board, board machine board, ICT line card board, automatic container operation does not stop, line body leakage, etc., field operators should press the emergency stop switch (power off), immediately notify the scene when the scene is protected Line engineer or technician handles.