Techniques for high speed (>100MHz) high density PCB design

o-leading.com

o-leading.com

2017-09-28 15:45:45

The size of the circuit board is fixed, if you need to accommodate more functional design, often need to improve the line density of PCB, but this may lead to enhanced mutual interference alignment, and walk the line carefully make impedance can not be reduced, please experts at high speed (>100MHz) high density in PCB design skills?

In designing high-speed, high-density PCB, crosstalk (crosstalk, interference) is really a special consideration because it has a major impact on timing (timing) and signal integrity (signal integrity). Here are a few points to note:

Select the proper termination mode.

Avoid moving up and down the two adjacent lines in the same direction, and even the line just up and down overlap, because this crosstalk than the same layer adjacent to the line is still larger.

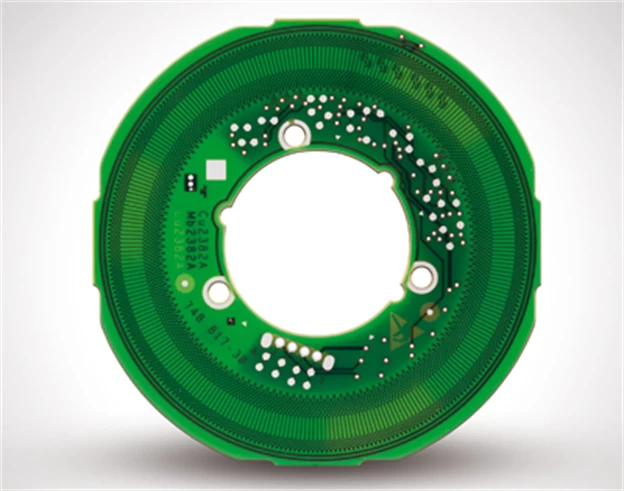

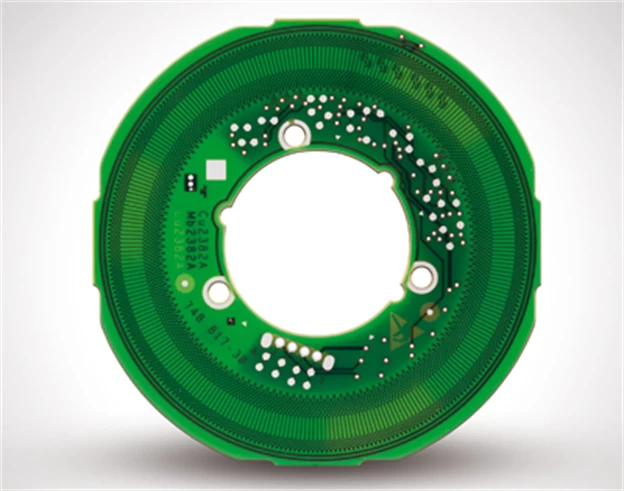

Use blind via (blind/buried) to increase the line area. But the cost of making PCB boards increases. In practice, it is difficult to achieve full parallel and equal length, but try to do as much as possible.

In addition, differential termination and common mode termination can be reserved to mitigate the impact on timing and signal integrity.

In designing high-speed, high-density PCB, crosstalk (crosstalk, interference) is really a special consideration because it has a major impact on timing (timing) and signal integrity (signal integrity). Here are a few points to note:

Printed circuit board supplier

Continuity and matching of characteristic impedance of control line.

The size of the line spacing. The distance usually seen is two times the line width. Simulation can be used to know the influence of line spacing on timing and signal integrity, and the minimum tolerable spacing is found. Different chip signals may have different results.

The size of the line spacing. The distance usually seen is two times the line width. Simulation can be used to know the influence of line spacing on timing and signal integrity, and the minimum tolerable spacing is found. Different chip signals may have different results.

Select the proper termination mode.

Avoid moving up and down the two adjacent lines in the same direction, and even the line just up and down overlap, because this crosstalk than the same layer adjacent to the line is still larger.

Printed circuit board company

Use blind via (blind/buried) to increase the line area. But the cost of making PCB boards increases. In practice, it is difficult to achieve full parallel and equal length, but try to do as much as possible.

In addition, differential termination and common mode termination can be reserved to mitigate the impact on timing and signal integrity.