How to consider the problem of impedance matching in high-speed PCB design schematic diagram design&

o-leading.com

o-leading.com

2017-10-10 21:57:57

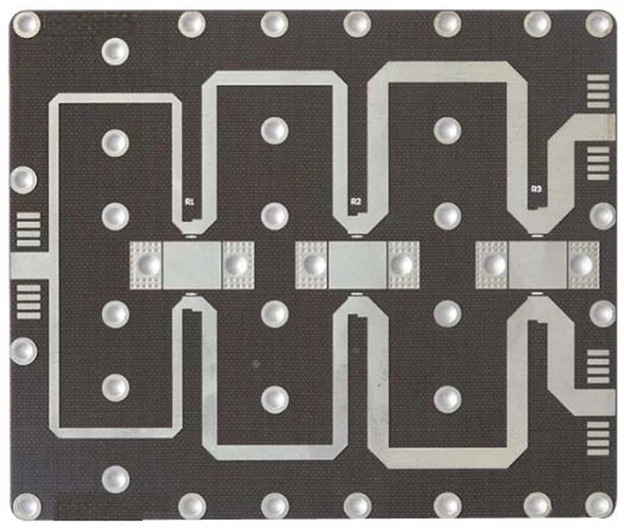

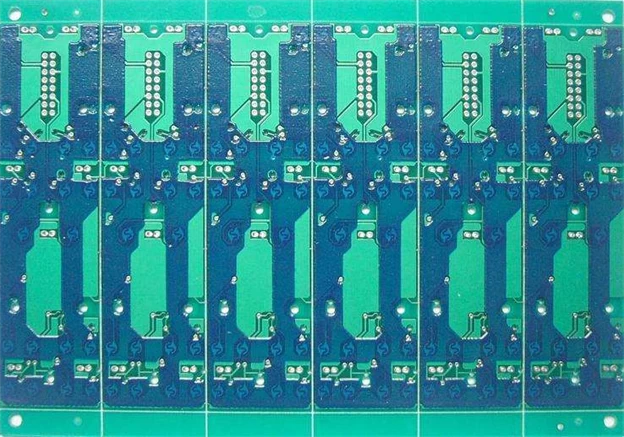

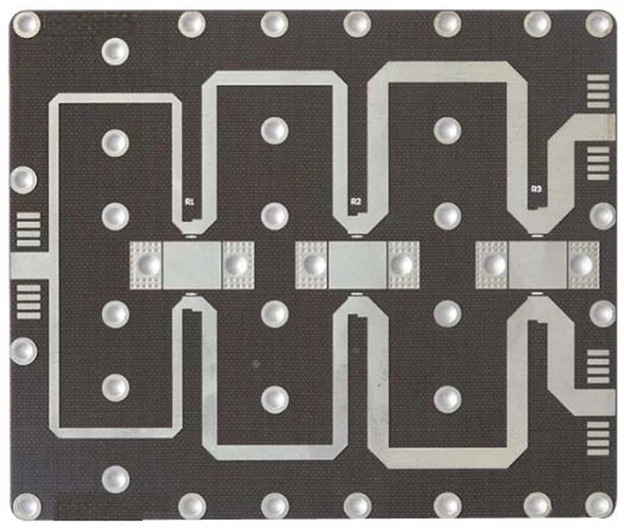

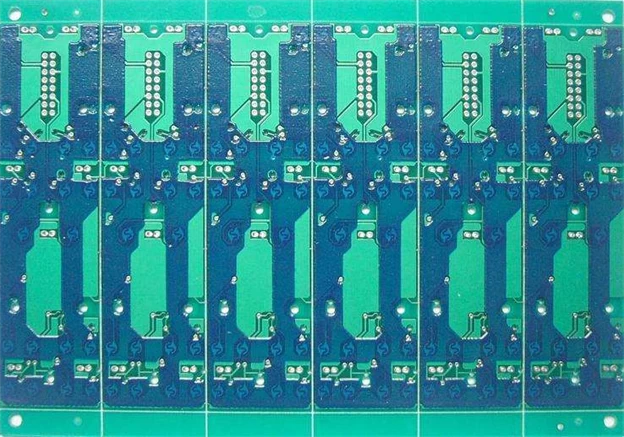

Impedance matching is one of the key elements in the design of high speed PCB circuits. The impedance value of the absolute relationship with the line, for example, is walking in the surface layer (microstrip) or (stripline/double stripline), and the inner layer (power reference layer or stratum) distance, line width, PCB material will affect the value of the characteristic impedance of wire.

That is to say, the impedance value must be determined after wiring. The general simulation software for mathematical model of line algorithm or the use of * * to consider some impedance discontinuities of the wiring, this time in principle only reserved some of the terminators (terminal), such as the series resistance, to alleviate the effect of line impedance discontinuities of the walk. The fundamental solution to the problem is to avoid the possibility of impedance discontinuities as much as possible during wiring.

Where can I provide a more accurate Library of IBIS models?

The accuracy of the IBIS model directly affects the simulation results. Basically IBIS can be regarded as the electrical characteristics data of the actual chip I/O buffer equivalent circuit, usually by SPICE model (and can be used to measure, but more, and * *) the absolute relationship between SPICE data and chip manufacturing, so the same devices of different chip vendors, the SPICE data is different then, the data model of IBIS after conversion will also vary in. That is to say, if they use A's device, only they have the ability to provide accurate model data for their devices, because no one else will know better what their device is made of. If the manufacturer's IBIS is not accurate, it can only continue to require the improvement of the company is the fundamental solution.

That is to say, the impedance value must be determined after wiring. The general simulation software for mathematical model of line algorithm or the use of * * to consider some impedance discontinuities of the wiring, this time in principle only reserved some of the terminators (terminal), such as the series resistance, to alleviate the effect of line impedance discontinuities of the walk. The fundamental solution to the problem is to avoid the possibility of impedance discontinuities as much as possible during wiring.

Where can I provide a more accurate Library of IBIS models?

The accuracy of the IBIS model directly affects the simulation results. Basically IBIS can be regarded as the electrical characteristics data of the actual chip I/O buffer equivalent circuit, usually by SPICE model (and can be used to measure, but more, and * *) the absolute relationship between SPICE data and chip manufacturing, so the same devices of different chip vendors, the SPICE data is different then, the data model of IBIS after conversion will also vary in. That is to say, if they use A's device, only they have the ability to provide accurate model data for their devices, because no one else will know better what their device is made of. If the manufacturer's IBIS is not accurate, it can only continue to require the improvement of the company is the fundamental solution.