Is there a difference between gold plating and immersion gold on PCB circuit boards?

In PCBA SMT processing, PCB circuit board production is a very important part. There are many process requirements for PCB circuit boards. For example, customers often require gold plating and immersion gold. These two processes are commonly used for PBC boards. It seems that the names are similar, but in fact there is a big difference. Many customers usually cannot distinguish the difference between the two processes. What is the difference between gold plating and immersion gold on PCB circuit boards?

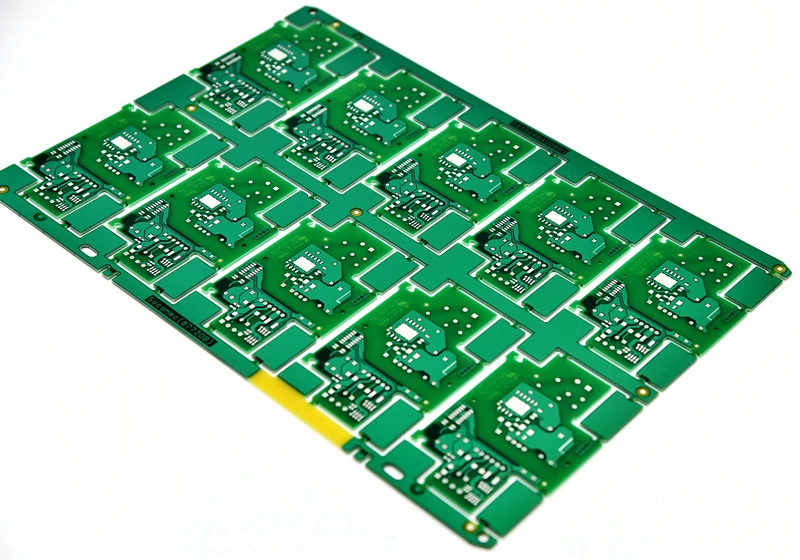

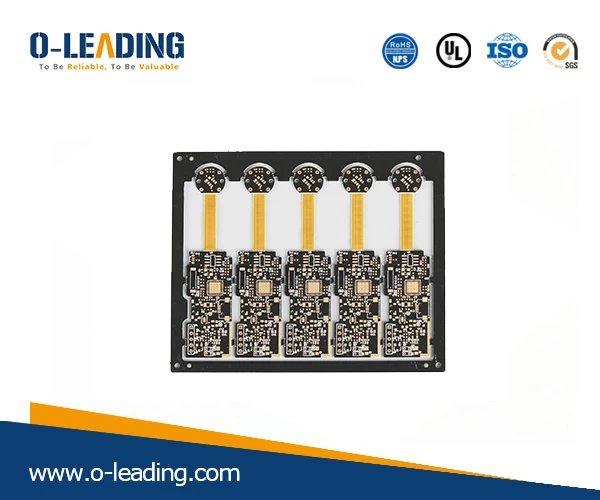

CERAMIC WAFER manufacturer china

Introduction of gold plating and immersion gold:

Gold plating: Gold particles are mainly attached to PCB boards by electroplating. Due to the strong adhesion of gold plating, it is also called hard gold. The gold fingers of memory sticks are hard gold, high hardness and wear resistance.

Sinking gold: A layer of plating is generated by a chemical oxidation-reduction reaction method, and gold particles crystallize and attach to the PCB pad. Because of its weak adhesion, it is also called soft gold.

The difference between gold plating and immersion gold:

1. The gold plating process is performed before the solder mask in the chip processing. It may appear that the green oil is not cleaned and it is not easy to tin; the immersion gold process is done after the solder mask, and the chip is easy to tin.

2. Before the gold plating process is usually performed, a layer of nickel is usually required, followed by a layer of gold. The metal layer is copper-nickel-gold, because nickel is magnetic and has an effect on shielding electromagnetics. The immersion gold process directly immerses gold on the copper skin. The metal layer is copper-gold, no nickel, and no magnetic shielding.

3. Gold plating is different from immersion gold, and the crystal structure formed is not the same, immersion gold is easier to weld than gold plating, and it will not cause welding failure. Moreover, immersion gold has a denser crystal structure than gold plating, and is less prone to oxidation.

4. The flatness of the gold-plated circuit board is not as good as that of sinking gold. For boards with higher requirements, the flatness is better. Generally, sinking gold is used, and sinking gold generally does not appear after assembly.