Gold, silver, copper in the PCB

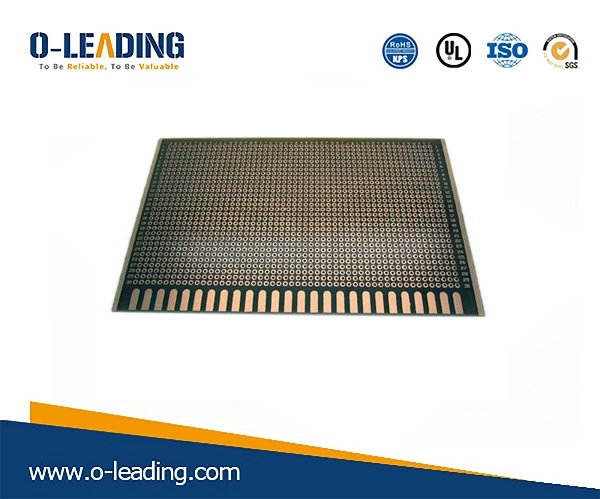

The PCB is a support for electronic components and is a carrier for electrical connection of electronic components, mainly for supporting and interconnecting. From the outside, the outer layer of the board has three main colors: gold, silver, and light red. Classified by price: gold is the most expensive, silver is second, light red is the cheapest. However, the circuit inside the board is mainly pure copper, which is bare copper.3D printer PCB supplier.

It is said that there are still many precious metals on the PCB. It is reported that on average, each smartphone contains 0.05g gold, 0.26g silver, 12.6g copper, and the gold content of a laptop is 10 times that of a mobile phone!

Why are there precious metals on the PCB?

PCB as a support for electronic components, the surface of which requires soldering components, requires a portion of the copper layer to be exposed for soldering. These exposed copper layers are called pads. The pads are generally rectangular or circular, and the area is small. Therefore, after the solder resist is applied, the only copper exposed on the pad is exposed to the air.Printed circuit boards supplier.

The copper used in the PCB is easily oxidized. If the copper on the pad is oxidized, it is not only difficult to solder, but also the resistivity is greatly increased, which seriously affects the performance of the final product. Therefore, the pad is plated with an inert metal gold, or a layer of silver is chemically coated on its surface, or a special chemical film is used to cover the copper layer to prevent contact between the pad and the air. Prevents oxidation and protects the pad from ensuring yield during the next soldering process.