Attention! Common Fault Analysis of PCB Printed Circuit Board

o-leading.com

o-leading.com

2017-05-25 11:20:13

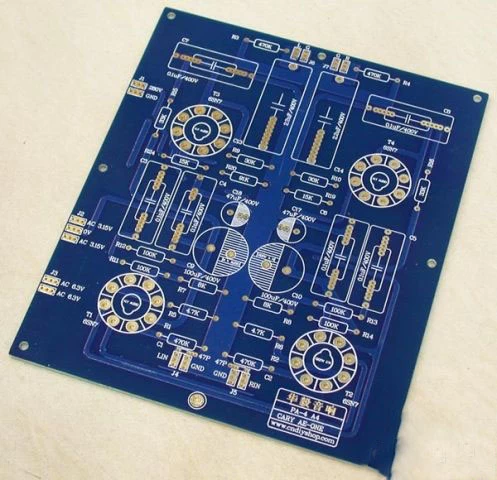

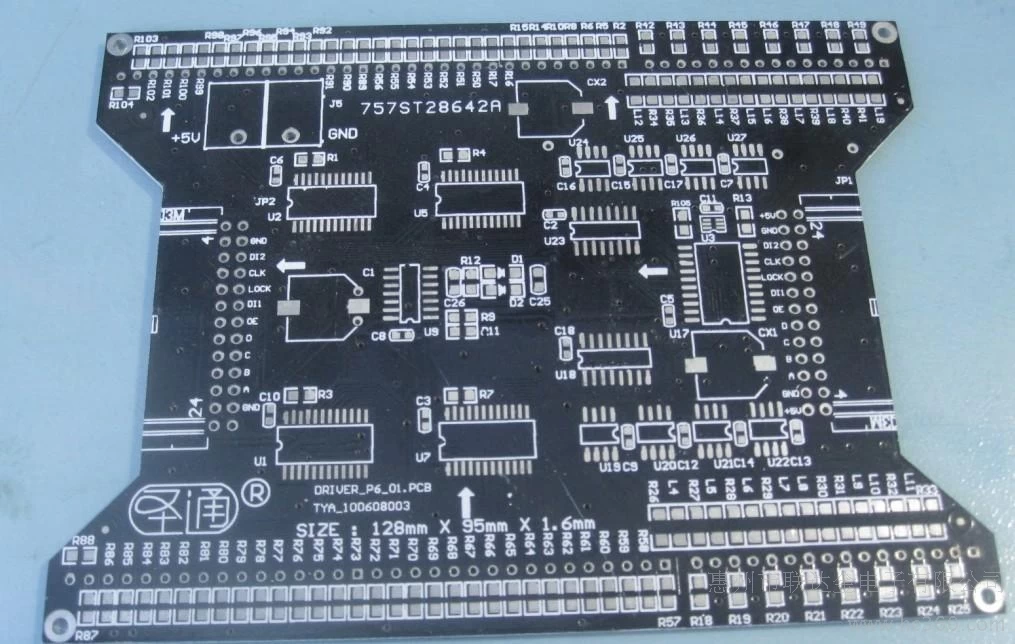

PCB commonly known as printed circuit boards, electronic components is an integral part. PCB in a series of production processes, there are many matching points, one accident will be flawed board, resulting in PCB quality problems emerge in an endless stream. So in the circuit board after forming, testing test has become an essential part of the link. Here to share with you PCB circuit board failure and its solution.

1, PCB board in the use of frequent stratification

Response measures: choose a good packaging, the use of constant temperature and humidity equipment for storage. Do PCB factory reliability test.

2, PCB board solder poor

Solution: purchase should be strictly concerned about the PCB factory quality control plan and the maintenance of the development of standards.

3, PCB board bending tilt

Measures: the sheet with wood pulp board pressure and then packaging and shipping, so as to avoid deformation later, if necessary, plus fixture in the patch to prevent the device over the weight of the board. PCB in the packaging before the need to simulate the placement of IR conditions to test, so as to avoid the furnace after the bending of the bad phenomenon.

4, PCB board impedance is poor

Response: Requires the manufacturer to send the batch test report and impedance bar.

5, anti-welding bubble / off

Response: PCB suppliers to develop PCB board reliability testing requirements, in different production processes to be controlled.

6, martyr effect

Response measures: manufacturers need to pay close attention to the production process in the gold and copper between the control of the potential difference.