Which circuit is the best for use: Traditional Printed Circuits vs. Flexible Circuits

o-leading.com

o-leading.com

2017-06-26 15:36:16

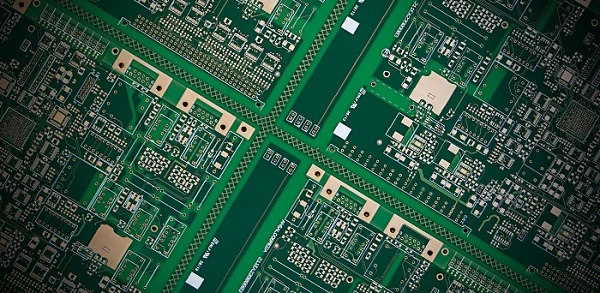

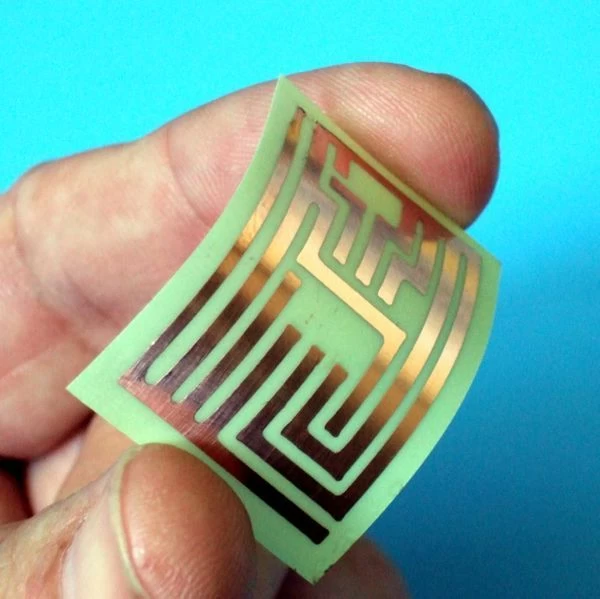

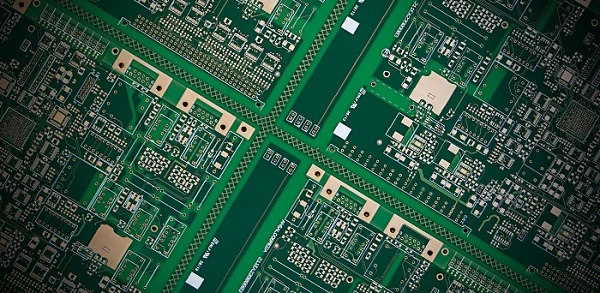

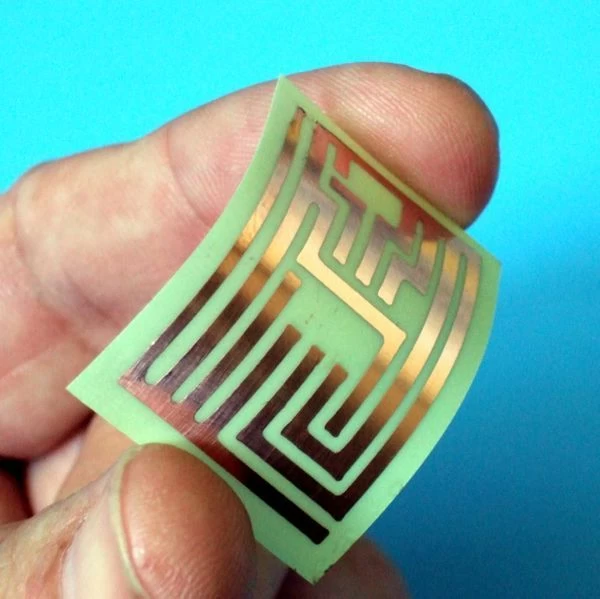

Printed Circuit Board, which is an important electronic part to load electronic components and connection carrier of electronic components conduction. Just like any other electronic components, PCBs have experienced tremendous changes and improvements especially with technological advancement. One of these achievements is the invention of the flexible PCBs which are basically vast arrays of conductors bonded to thin dielectric films.

Do you know which PCB is better the best for your use? The following introduction will help you understand the differences between traditional and flexible circuits better.

Traditional PCBs are less complicated to design and assemble compared to flexible, they can be easily subjected to automate assembly. This is due to the fact that they are rigid and they can easily endure wave soldering and IR (Infrared) reflow soldering. But Flexible circuits pose a problem in automated assembling due to the complexity of the circuits. In the same time, the flexibility of these PCBs makes a problem when take them through all the assembly stages.

Flexible circuits absorb moisture fairly well and they should be baked out before being taken through high temperatures. The same solder paste screening procedure is also the same for both the traditional and flexible circuits. However, after the solder paste screening point, care must be taken since the procedure involved in each of the circuits is quite different. The next procedure will be the pick and place step which mounts some pressure on the circuits. Flexible circuits should be protected during this procedure to provide for stability and for reliable placement of the components. Stability of flexible circuits is also needed in the soldering process where all the components are soldered into their designated positions. After the components are soldered into place, they are cleaned, re-worked and inspected. After this procedure, stability is no longer crucial for the flexible circuits thus the stability figure that was added during can be eliminated for the completion of packaging and shipment tasks.

Traditional PCBs are less complicated to design and assemble compared to flexible, they can be easily subjected to automate assembly. This is due to the fact that they are rigid and they can easily endure wave soldering and IR (Infrared) reflow soldering. But Flexible circuits pose a problem in automated assembling due to the complexity of the circuits. In the same time, the flexibility of these PCBs makes a problem when take them through all the assembly stages.

Flexible circuits absorb moisture fairly well and they should be baked out before being taken through high temperatures. The same solder paste screening procedure is also the same for both the traditional and flexible circuits. However, after the solder paste screening point, care must be taken since the procedure involved in each of the circuits is quite different. The next procedure will be the pick and place step which mounts some pressure on the circuits. Flexible circuits should be protected during this procedure to provide for stability and for reliable placement of the components. Stability of flexible circuits is also needed in the soldering process where all the components are soldered into their designated positions. After the components are soldered into place, they are cleaned, re-worked and inspected. After this procedure, stability is no longer crucial for the flexible circuits thus the stability figure that was added during can be eliminated for the completion of packaging and shipment tasks.

We are pcb manufacturer in china and china Rigid-flexible pcb manufacturer. we can provide you superior Quick turn pcb Printed circuit board, if you need these products, please contact us.