PCB laser marking machine helps PCB industry develop rapidly

2018-05-31 11:53:04

As an important electronic connector, PCB is used in almost all electronic products. It is considered to be the "mother of electronic system products." Its technological changes and market trends have become the focus of many companies.

As an important electronic connector, PCB is used in almost all electronic products. It is considered to be the "mother of electronic system products." Its technological changes and market trends have become the focus of many companies.

At present, PCB marking processing mainly includes screen printing and laser marking.

The traditional silk screen processing is rough, and the label is easy to fall off to the user and cause inconvenience. In addition, silk screen printing procedures are cumbersome, requiring operators to replace them in time to ensure production efficiency and increase labor costs.

As an important electronic connector, PCB is used in almost all electronic products. It is considered to be the "mother of electronic system products." Its technological changes and market trends have become the focus of many companies.

At present, PCB marking processing mainly includes screen printing and laser marking.

The traditional silk screen processing is rough, and the label is easy to fall off to the user and cause inconvenience. In addition, silk screen printing procedures are cumbersome, requiring operators to replace them in time to ensure production efficiency and increase labor costs.

The laser marking machine, with its precision and flexibility, can make up for the insufficiency of silk screen processing and gradually become the best tool for PCB marking. It will play a decisive role in the circuit board industry!

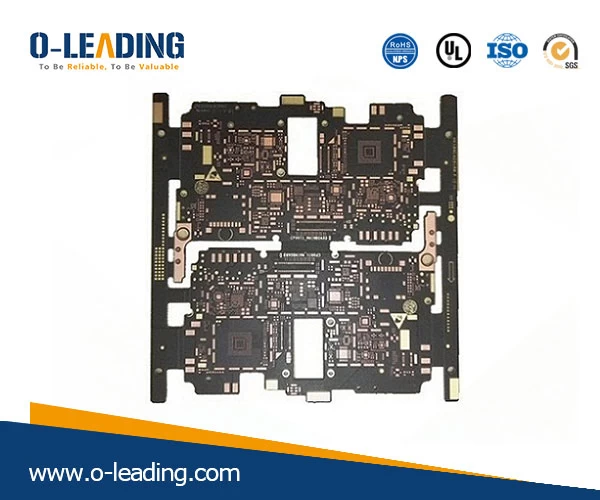

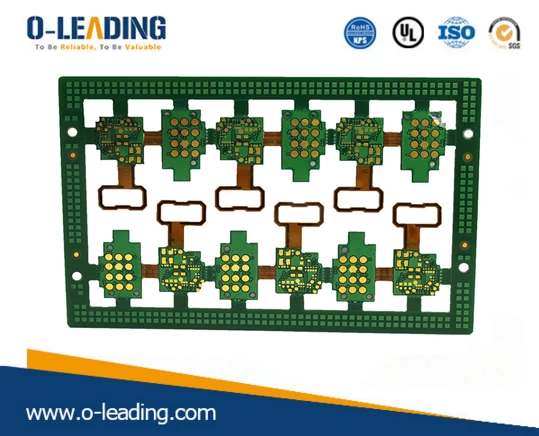

PCB( printed circuit boards supplier ) laser marking machine is a special model that is specially used to mark bar code, two-dimension code and characters, graphics and other information on the printed circuit board. Using the PCB laser marking machine to mark the information on the circuit board, it can record the relevant production information of the circuit board, realize the control of product information in the production process, and achieve the traceability of the electronic product's full life cycle.

High-precision: Laser marking is precise and non-contact processing. It can make fine lines less than 0.1mm and characters and numbers within 0.5mm on the surface of the material. It is especially suitable for the circuit board which requires extremely small graphics and texts. Identification.

Safety and environmental protection: only a small amount of gas is generated and discharged through ventilation, and no chemical assistance is required to protect the operator's safety and working environment as much as possible.

High quality: The electronic chip has high requirements for marking quality, clarity and permanence. The laser marking machine can realize the permanent marking of the chip, and does not fade away due to external factors such as high and low temperature, acidity, and friction.