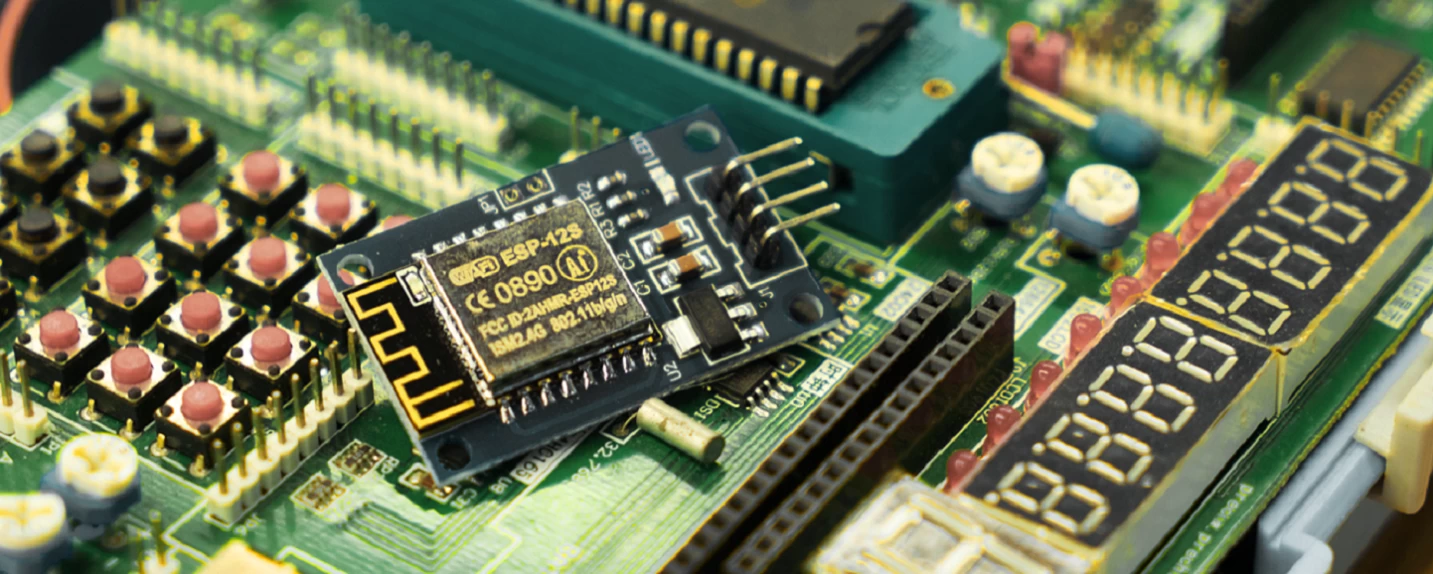

Rigid Flex PCB Manufacturing

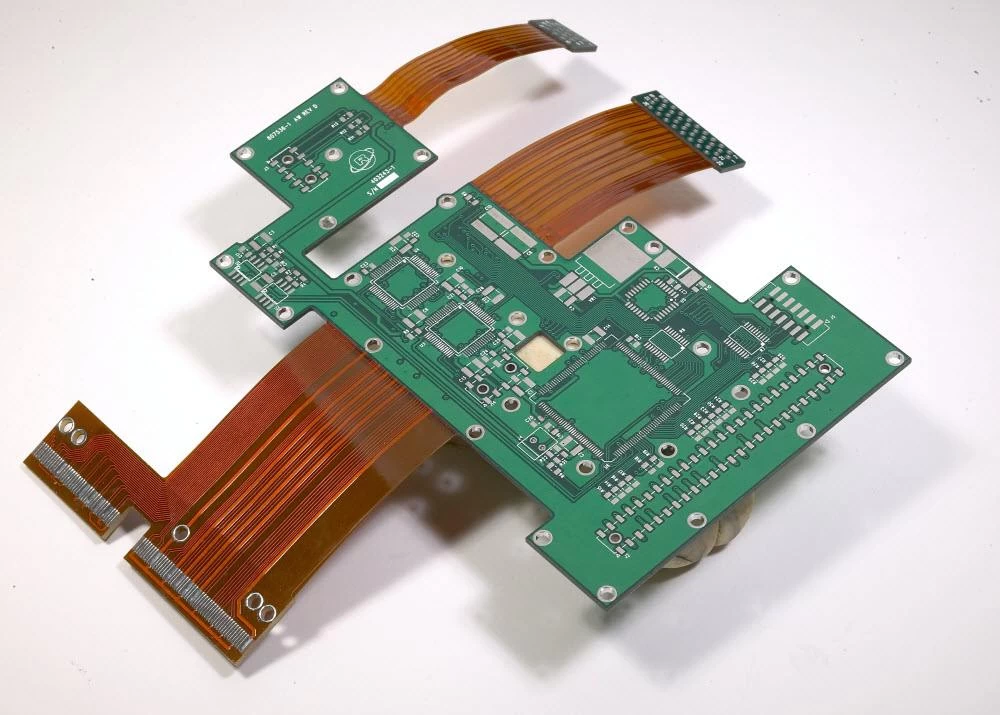

The development of PCB and FPC led birth of rigid flex boards. Rigid flex printed circuit boards are PCBs using a combination of flexible and rigid board technologies. Rigid flex boards are PCBs with combination of FPC and PCB. First, electronic engineers draw circuits and shape according to production requirements. Then the order will be issued to factory with production capability of soft and hard combined PCB board. After CAM engineers process the file, then arrange FPC and PCB production lines to finish PCBs. These two kinds of boards will be seamlessly laminated. Due to high complex production process control and value, all rigid flex PCBs should be 100% detected before shipment.

Capabilities: Flexible Circuit Boards

Flex

PCBs (Flexible Printed Circuit Boards) are printed circuit boards that are

bendable, either bent once as they are being

installed like those in a

miniature camera, or bent multiple times (even continuously) like those in an

inkjet printer.

Flex PCBs can

be single-sided, double-sided, or multi-layered. They can have stiffeners to

provide areas of non-flexing, or

they can be part of a rigid-flexible assembly

to allow a rigid PCB to be bent on assembly.

Flexible PCB Uses

Reducing

both labor cost and assembly size, flexible PCBs are used increasingly in

electronic assemblies. Some of the uses for flexible

PCBs:

•

Automobiles

• Cameras

• Cell Phones

• Military Electronics

• Avionics

• Computers

• Tablets

Flex PCB Advantages

Flexible Printed Circuit Boards have advantages over rigid PCBs, ribbon cable, and discrete wiring:

•

Reduction in overall package size/weight

• Fewer assembly errors

• Increased reliability

• Increased control of impedance/inductance

• Improved heat dissipation

• Allows for a 3-dimensional packaging scheme

• Improves the appearance of the package

Flex PCB Issues

Where

components are attached or where the flexible circuit board is to be bent as it

attaches to non-flexing circuits, stiffeners are required.

This prevents damage

to both the connections and the Flex PCB.

Flexible

PCBs, by their nature, are made to odd shapes; they aren’t a convenient

rectangle. After the Flex PCB is manufactured,it has to be

routed, or skived,

to shape it to fit. To make sure that the edges of the circuit traces are not

going to be damaged in the process of routing,

care must be taken in the layout

and design stages to keep the circuit traces back from the edge.

When

there will be continuous or dynamic flexing of the circuit material, special

considerations are needed. On multi-layered Flex PCBs,

this includes taking

into account the number of layers while making sure that the conductors will

not be fatigued when the PCB is flexed.

Flexible printed circuit boards from O-Leading PCB China are designed and fabricated to the highest quality standards.

For more information about Flex PCBs, contact us at sales@o-leading.com