The Meaning of SMT in Electronic Processing

o-leading.com

o-leading.com

2017-04-17 18:26:01

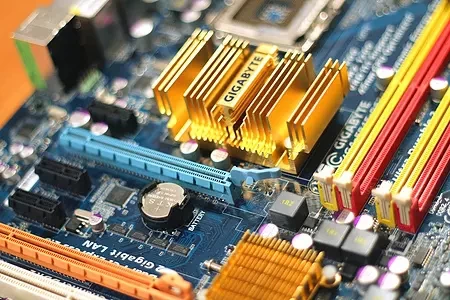

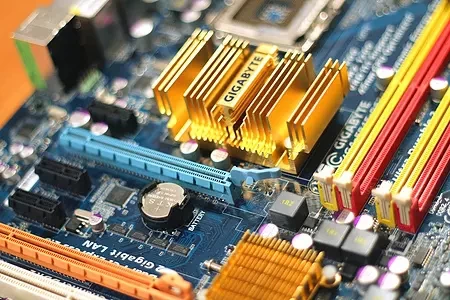

SMT is an abbreviation of Surface Mount Technology, which is the most popular technology and process in the PCB assembly industry and achieved miniaturization of electronic product assembly, high reliability, high density, low cost and production automation. SMT is directly to make the surface mount component welding to the specified PCB placement, The electronic mechanical and electrical connection of electronics assembly technology is constitute of using soldering materials between parts and printed circuit board.At present, the surface mount technology has been widely used in the assembly of electronic products , especially in computer and communication products.

Surface mount electronic products are generally made up of printed circuit boards and surface mount parts. Printed Circuit Board (PCB) includes single-sided with containing lines and pad or double-sided multilayer materials . Surface Mount parts is mainly classified as surface mount parts and surface mount devices. Surface mount parts refer to various types of passive components, such as resistors, capacitors, inductors, etc; the surface mount device is using a packaged electronic device, which usually refers to a variety of active devices, like Small Outline Package (SOP), Ball Grid Array (BGA), and so on. The printed circuit board and surface mount parts is to complete the surface mount work through surface mount technology .

Surface mount electronic products are generally made up of printed circuit boards and surface mount parts. Printed Circuit Board (PCB) includes single-sided with containing lines and pad or double-sided multilayer materials . Surface Mount parts is mainly classified as surface mount parts and surface mount devices. Surface mount parts refer to various types of passive components, such as resistors, capacitors, inductors, etc; the surface mount device is using a packaged electronic device, which usually refers to a variety of active devices, like Small Outline Package (SOP), Ball Grid Array (BGA), and so on. The printed circuit board and surface mount parts is to complete the surface mount work through surface mount technology .