Apple wants to change the life of the motherboard, PCB manufacturers have the future?

o-lead

o-leading.com

2018-06-12 15:28:43

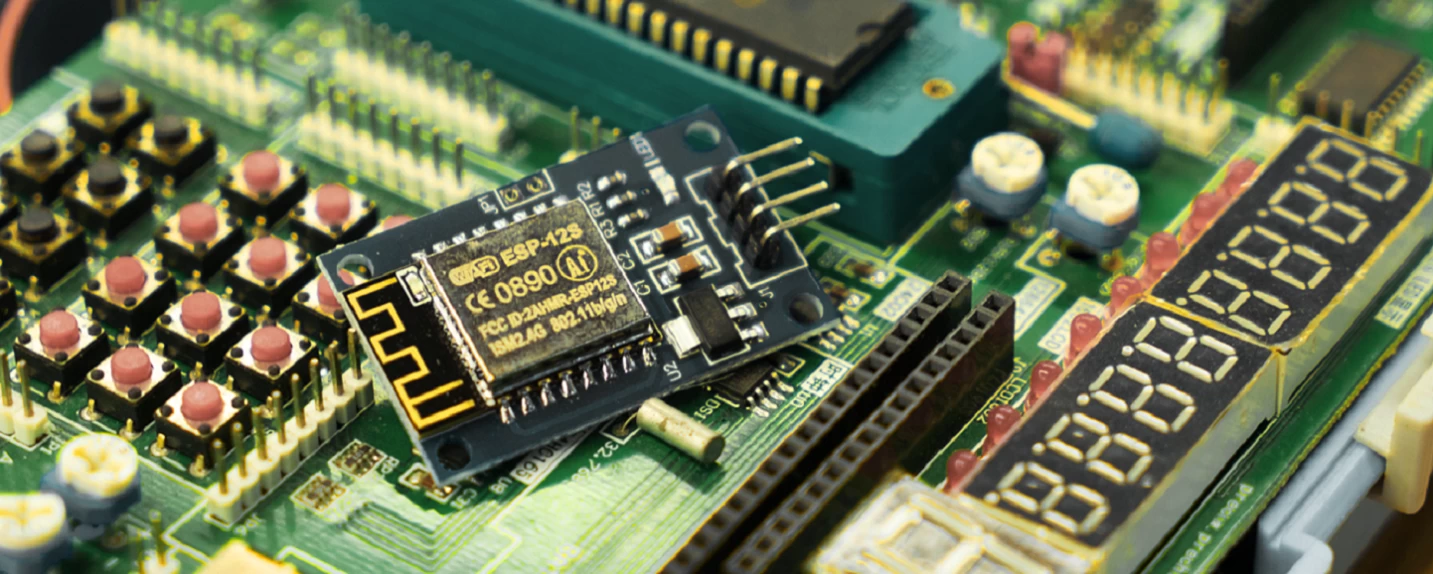

In terms of hardware technology, the biggest highlight of the iPhone 8/8P and iPhone X is the A11 bionic processor it brings. It is understood that the A11 uses the TSMC InFoWLP technology used in the A10 processor, but the process is reduced from 16nm to 10nm, which is one of the important reasons for its small size and improved performance. It is worth noting that, in the motherboard corresponding to the 10nm process, it has revolutionized the PCB industry's fine line manufacturing technology mSAP (improved semi-additive method) into the PCB industry, or started a new round of motherboard revolution. .

In fact, this technology evolution of the motherboard also has a proper term: Substrate-Like PCB (SLP).

What is a class carrier?

Nowadays, smart phones generally use HDI high-density interconnect boards as their PCB solutions. A small circuit board can carry a large number of chips and circuit components. However, with the further development of miniaturization of electronic products, HDI at any level has gradually failed to meet the requirements of manufacturers.

Compared to HDI, the class carrier board further shortens the line width. It is reported that the line width of the HDI is approximately 50 microns, while the specification of the class carrier board is 30 microns. At the same time, the accuracy of the carrier board is higher than that of the conventional HDI board, but the accuracy level cannot reach the IC carrier board. It is a product with a performance in between. Therefore, although the class carrier board is a PCB hard board, it can provide a platform for more sophisticated circuit components.

It is worth mentioning that after the iPhone 8/8P and iPhone X introduced the class carrier board, Samsung's newly released Galaxy S9 also used a class carrier board. Driven by Apple and Samsung, I believe that in the future there will be more and more smart phones that choose to adopt class-based boards.