Fundamental Characteristics of a High Reliability Printed Circuit Board

o-leading.com

o-leading.com

2017-06-29 10:52:21

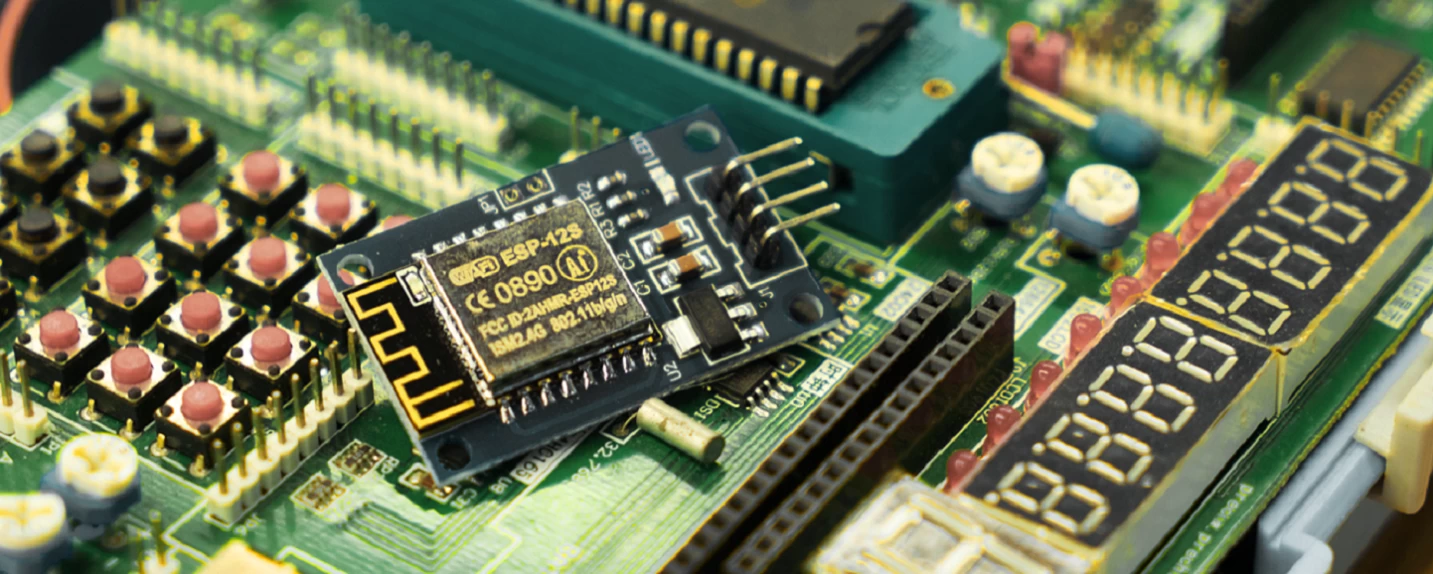

High reliability is the goal for many designers and final users of High Quality PCBs china. Since all the components are mounted on the PCB, it is expected that the PCB delivers some consistency and efficiency over time depending on the operating conditions like temperature and humidity levels. Reliability is, therefore, crucial for any PCB regardless of its use and the stage (assembly stage or manufacturing) where it is used. Consequently, it is important to determine the reliability of PCB materials through testing and through observing the data sheets provided by the manufacturer.

Improves the resistance of the z-axis expansion where PTHs (Plated Through Holes) are metalized and drilled through the material thickness to form ground connections and form signals.

No maintenance is required since welding is done perfectly and there are no repairs needed.

Risks like electrical shock due to open circuits are eliminated.

High reliability

The calibrations are made according to an international standard hence measurements and operations can be done by an expert from any part of the world.

Reduction of risks of flaking or the loss of adhesion.

Higher capacity to fight a mechanical force regardless of its magnitude

Implementing the program helps ensure that all specifications are fitted you need. We are china Pcb design company, the best choice for you.

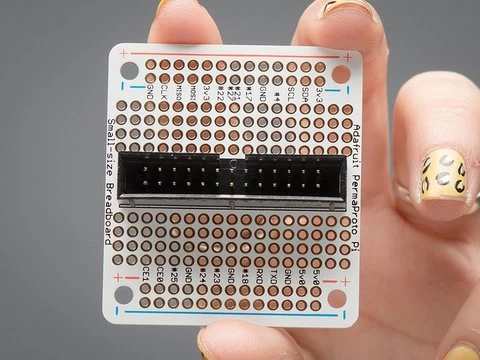

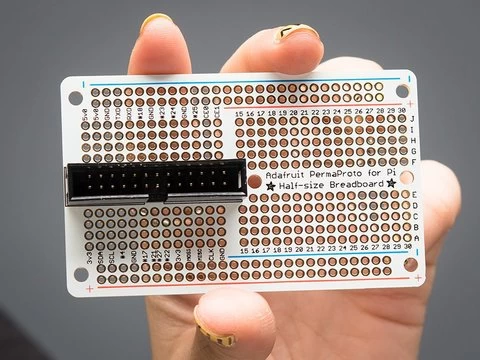

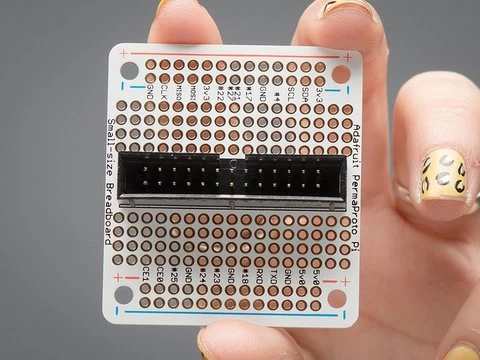

- Hole wall with copper thickness with 25 micron

Improves the resistance of the z-axis expansion where PTHs (Plated Through Holes) are metalized and drilled through the material thickness to form ground connections and form signals.

- Absence of welding repairs or breaks in line repair

No maintenance is required since welding is done perfectly and there are no repairs needed.

Risks like electrical shock due to open circuits are eliminated.

- Failure to adhere to IPC cleanliness specifications

- Controlling the life of treatment surface

High reliability

- Reduces the risk of moisture intrusion

- Ensuring CCL tolerances adhere to IPC4101ClassB/L requirements

- Using internationally recognized base like IEE for the PCB

The calibrations are made according to an international standard hence measurements and operations can be done by an expert from any part of the world.

- Defining the mechanical features of the PCB like holes and shapes

- Defining solder material and ensuring compliance to the IPC-SM-840ClassT standards

- Definition of the repair and appearance requirements

- Solder resist layer with a thickness similar to that recommended by NCAB

Reduction of risks of flaking or the loss of adhesion.

Higher capacity to fight a mechanical force regardless of its magnitude

- Use of peelable gums models and brands like PetersSD2955

- Requirements of the plug hole depth

- Using NCAB approval procedures for each single order