Which is more economical than PCB-based SMT processing?

With the development of the times, social changes have become more frequent, and the reshuffling speed of the electronics industry has become faster and faster, full of many uncertainties. Many incidents of black swan and gray rhinoceros have become facts. The competition of enterprises in the future will be an infinite enlargement at a certain point, and the core competitiveness of enterprises becomes more and more important. My way is consistent. If a company wants to have a breakthrough in the future, it must be a deep understanding of its own advantages and needs, and it is almost irreversible to focus on a certain breakthrough point and dig deeper than to focus on the entire process of control over the entire value chain. the trend of. Put it down to take it, you can have it, and give up some things in a timely manner to get the company to go further.

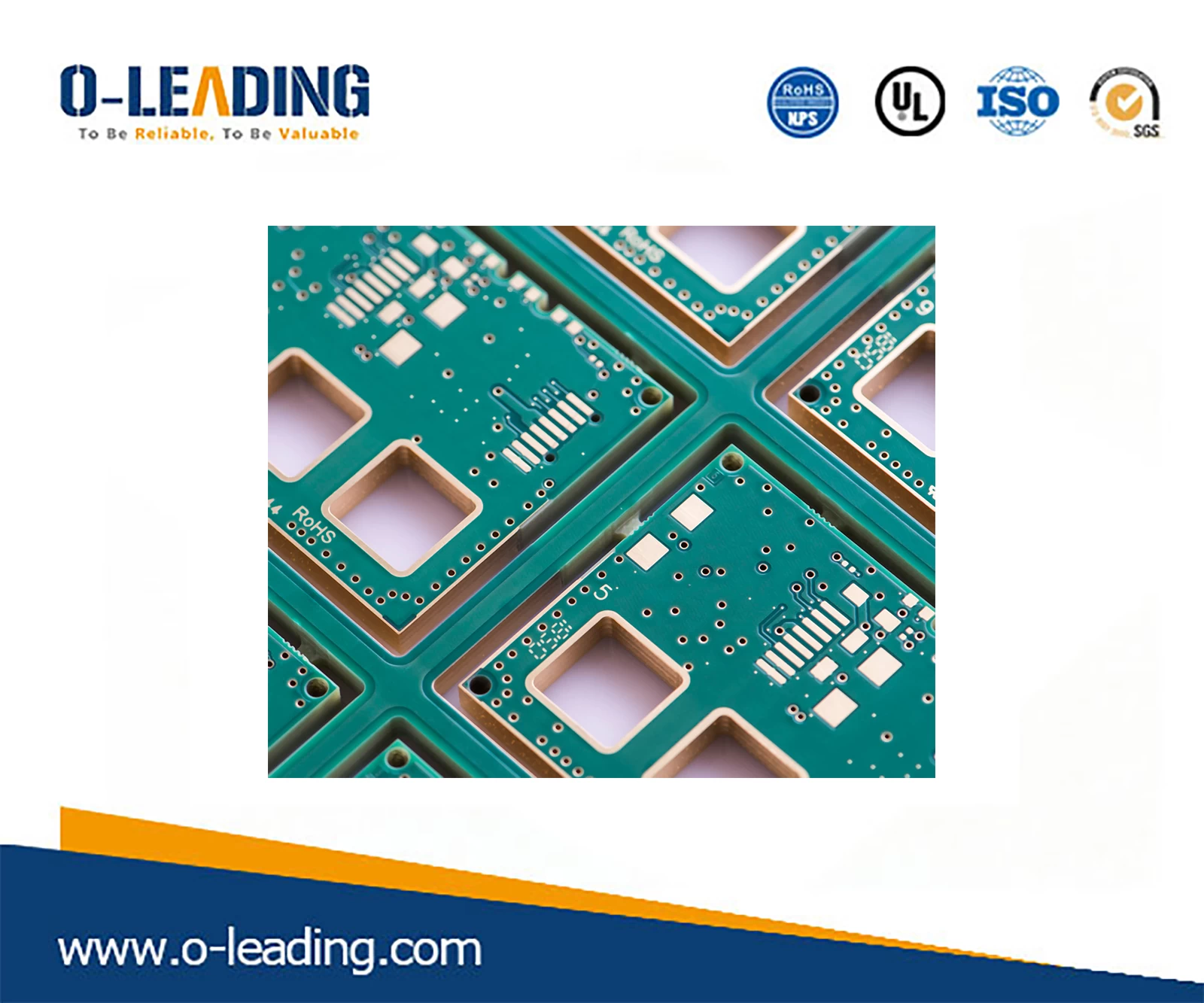

MCPCB Manufacturer china.

In view of this, all electronic product research and development companies, electronic product production and sales companies need to sink to carefully calculate the procurement cost of raw materials, inventory costs, personnel management costs, market opportunity costs, etc., and then compare PCB external SMT processing. The cost and the cost of the PCBA labor and materials package, you will be surprised to find that the PCBA labor and materials mode has reduced the overall cost of the company's PCBA electronics manufacturing, and the risk of the client's business has been greatly reduced. Handing professional things to professional people, on the surface, the individual prices have risen, but the actual overall costs have fallen sharply.

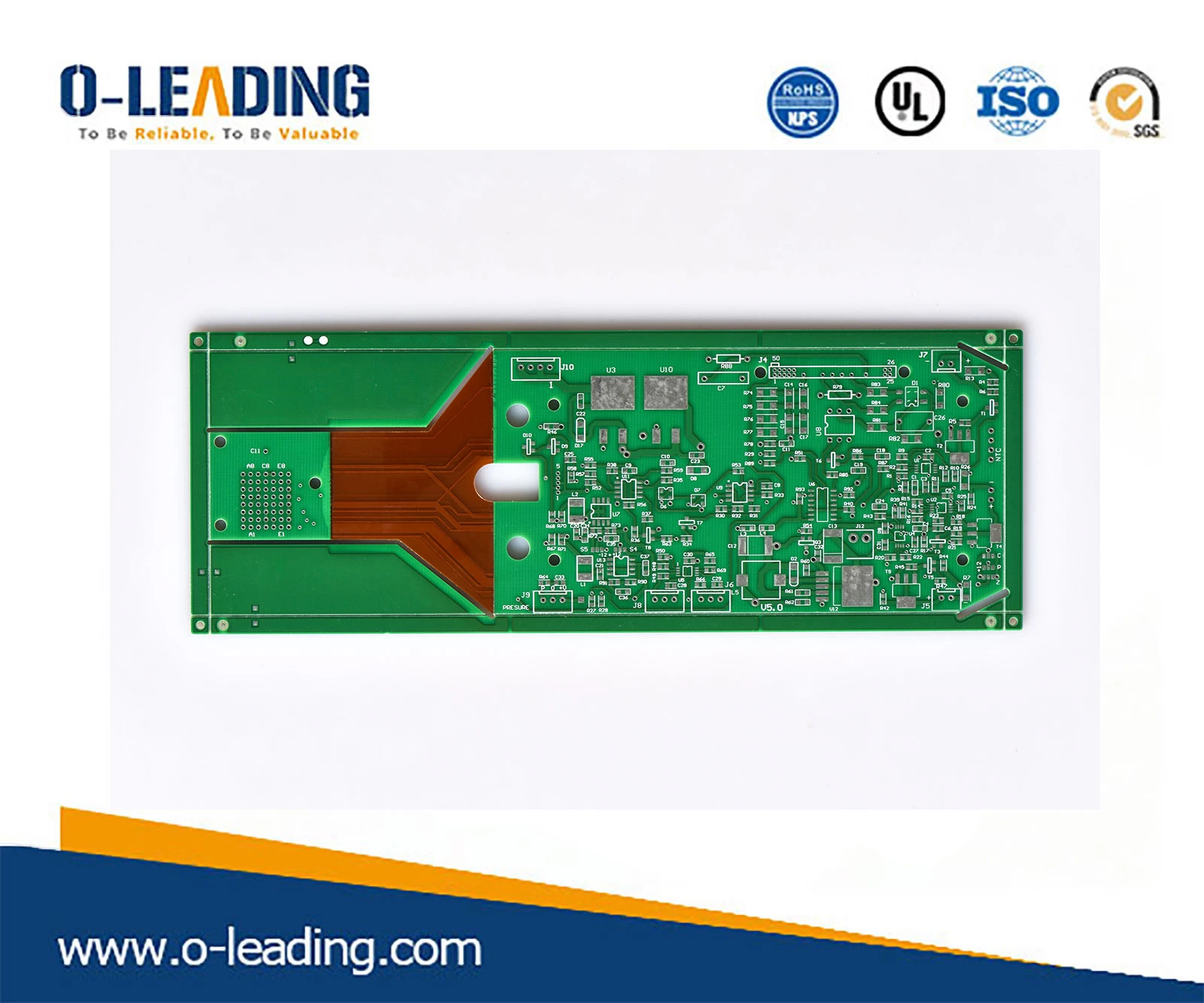

Aluminum PCB manufacturer china.

Nowadays, the mode of PCB SMT processing is less and less adopted by electronic product research and development companies. They are all looking for suitable PCBA labor and materials packaging service providers, and they only need to be a referee and arrange a few The personnel can carry out production tracking management. Many people may question the issue of capital flow, claiming that PCBA labor and materials processing generally requires about 70% of advance payment, which is not friendly to the company's capital turnover. The truth is that this is not much different from PCB SMT processing. Because many upstream materials such as ICs and various electronic components are also purchased in cash, there are not many suppliers that can make monthly payments.

After decades of development, the electronics manufacturing industry has long since passed, and the status quo of the electronics industry has developed extremely mature. The average profit margin of the electronic processing industry has been saturated, there is no profiteering phenomenon, and electronic processing companies have begun to fight for quality and service capabilities. PCBA's foundry materials (laboratory and encapsulation) processing mode can effectively replace the PCB SMT processing mode, reduce the comprehensive cost of personnel, warehousing, procurement, logistics, after-sales, and greatly gain the electronic product manufacturers who focus on core R&D and sales. Favor, we have reason to believe that the cooperation between electronics manufacturers and PCBA OEMs will take a new step in the future.