The first article on PCB industry trend analysis on 2017

o-leading.com

o-leading.com

2017-04-10 18:42:39

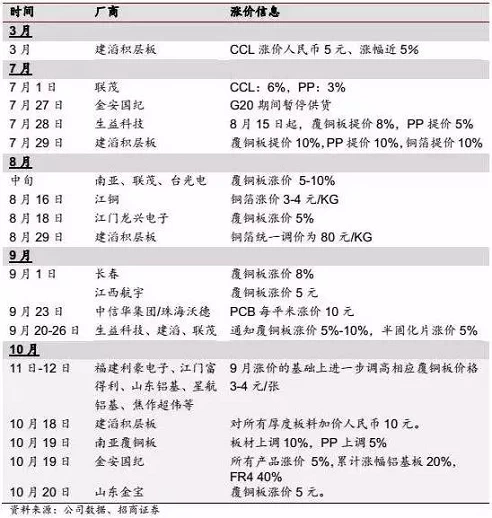

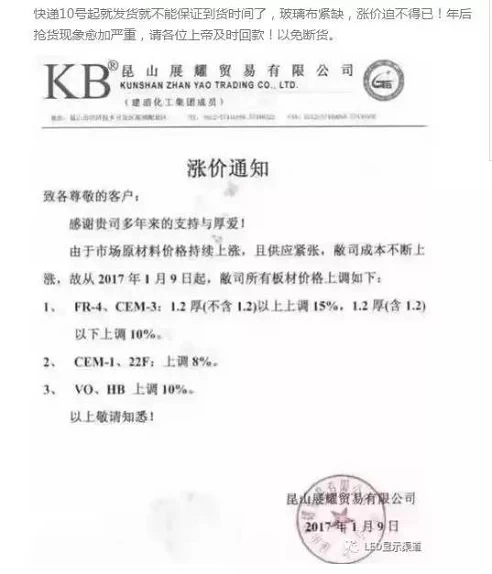

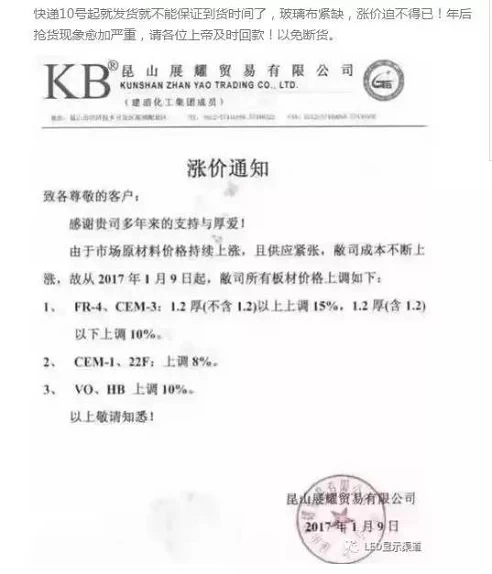

It is known that less than 1 months in 2017, PCB board has suffered a new round of price increases, PCB raw material prices rose 5% again in this round of price boom. Compared with the previous price increase, the only difference this time is that the increase for the price of PCB board is mainly aimed at above 1.2mm thickness (equal or more) and high grade products.

For many small and medium-sized PCB factories, because there is no spare money to prepare the goods in advance, at the end of last year when a customer to talk about prices, but the upstream materials suppliers increased price again, Jan and Feb months are peak shipments period for the the downstream pcb factories , limited working days because of CNY holidays, PCB factory may not be on time delivery. In fact, in recent years, the price of raw materials have been falling, the demand has been increased year by year, this has also caused a lot of PCB enterprise out of the market because of the price war.

"Big enterprise has large amount of raw materials procurement, have certain bargaining chip. But small enterprise didn't have this kind of bargain ability, we can rise as we want, otherwise, we won't supply. As a result, the downstream small factories’ cost will be increased, increased difficulties of survival, and will accelerate the merger and acquisition, integration, industry reshuffle." A PCB raw material manufacturers’ person in charge ,who said like this, think CCL copper clad and raw materials will continue to rise, as a result, it has a price but no sales, some micro-small and medium-sized pcb factories, who will suffer a greater impact and may have the risk capital chain rupture in 2017.

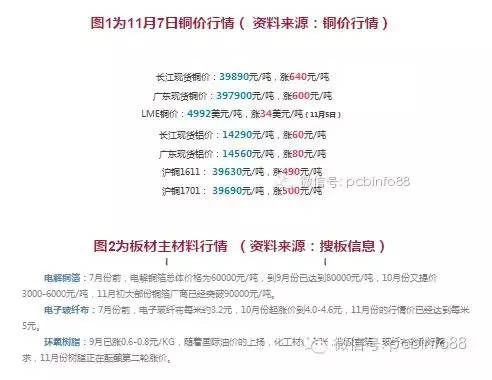

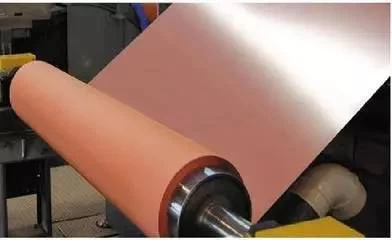

Since early 2016, PCB standard copper foil prices have risen more than 50%, copper foil processing fee and effective CCL copper clad price has been higher than the original average by above 100% and 50% respectively. In early November 2016, the original copper prices soared to 48000 yuan/ton, due to the original copper prices rose 26%, the impetus of increasing in the price of electrolytic copper foil is transferred from the processing fee to the original price of copper, electrolytic copper foil overall prices have broken through 110000 yuan/ton. According to Taiwan media reports, in January 2017, copper foil processing appeared again a small increase.

Copper foil is in short supply in the past year, in March last year,after KB, who has the highest market share & has the deep influence of the largest copper clad companies send the price increase notice, following KB step, other raw material merchants began to rise, stimulate the upstream and downstream supply chain also fully follow up.

Difficult expansion, the increase in the price of copper foil, CCL, out of stock , When alleviate?

Copper foil and copper clad and PCB manufacturers long-term struggle in the bottom of supply chain, who never think that lithium battery which used on electric car was born, this round increasing is so rapid and sustained in raw material cycle, this boom is more because electronic copper foil production changed into lithium electricity copper foil production.

According to the market news, since the first quarter of 2017, the PCB industry from upstream equipment factory, raw material factory to downstream manufacturers are present slack-season isn’t slick. One is, electronics car plate board increase the proportion, increased from 0.5 square meters of copper foil substrate to 2 square meters of that; The second ,it’s said that in the second half year, the Apples (iPhone8) will use line width, line spacing smaller "Substrate Like - PCB" (Abb. SLP) technology, it will replace the previous HDI PCB technology.

If considering the CCL, PCB companies generally promote inventory stock up , the supply of copper foil will be more nervous.

It is reported,orders for production equipment to provide lithium electrolytic copper foil for new energy vehicles has arranged to the second half of 2017, estimates the status of the shortage of the copper foil, CCL, PCB manufacturers have to suffer at least a year and a half to two years. Two or three years later, probably due to the lithium battery furious competition of new energy vehicles, some copper foil production enterprises again return to CCL and PCB.

PCB industry is how to break through?

Copper foil prices remain high. Most PCB factories started already after CNY holiday, although the raw material supply situation will be more nervous, but the new energy vehicles production has gone to the off-season, part of the copper foil factory has changed capacity back to PCB copper foil market, there are some PCB factories who prepared in advance, the actual supply is not so nervous.

In fact, the CCL price is only 1/3 of the total price of PCB, the proportion of copper foil price impact on the CCL is far more than that of impact on the PCB, PCB market in long-term vicious competition, large pcb factories’ price increase range isn’t big, but the small and medium-sized enterprise has to rise in price. However, large pcb factories themselves price are far higher than small and medium-sized enterprise and large pcb factories has big MOQ limited.

Most of the small and medium-sized PCB factories don't have enough cash to hoard the PCB raw material, purchasing cycle is very short.Raw material price increase, which cause an increased demand for cash,so capital chain is tension. Because production is not large, the proportion of profit is highly influenced by CCL price. Both let the small and medium-sized PCB factory suffer CCL price increases, so they has to send the price increases notice.

On the one hand, the PCB factories in 2017 when bargaining with the customers, they know now market, may not require products on sale. PCB manufacturers may change the old payment term to new payment term, old is to pay after shipment, new payment term is to pay before shipment.Board out of stock is inevitable, PCB suppliers/factories shold have a long-term plan.

On the other hand,this crazy is not sustainable, copper foil market continued high fever, there are the hype factors.The lithium electricity copper foil demand won’t increase month by month, also won't high-speed expansion. Among PCB factories,they should keep the rational competition, should not blindly follow suit, bidding & stocks & price war again, careful consideration on purchase varieties and quantity,couldn’t disorderly restock.

As the new energy cars, mobile phones, LED small spacing, communication base stations and other major electronics segment market demand, the PCB industry market gradually warming, PCB factories should seize the opportunity, improve their own quality, strives for perfection, improve yield, reduce cost and avoid vicious competition, this is the way to break through.

For copper foil industry, they should make full use of the time price rise to improve product technology and quality, promote technical progress of copper foil. Now into the era of high frequency and high speed material,China PCB factories basically can't make, Taiwan manufacturers can't make either, all of them are specified to make by Japan manufacturers. For copper foil factory doesn’t have profit and no technology investment , so they are no technological progress, this kind of enterprise can't last for a long time. This kind of industry chain is unhealthy, adverse also to our own, and now the copper foil factory, should take the good opportunity to increase investment in research and development, which is undoubtedly helpful for industry.

In the long run, the raw material price increase will speed up out the micro, small and medium enterprises who are not competitive, which will enable industry return to rational range, conducive to the healthy development of the industrial chain.

For many small and medium-sized PCB factories, because there is no spare money to prepare the goods in advance, at the end of last year when a customer to talk about prices, but the upstream materials suppliers increased price again, Jan and Feb months are peak shipments period for the the downstream pcb factories , limited working days because of CNY holidays, PCB factory may not be on time delivery. In fact, in recent years, the price of raw materials have been falling, the demand has been increased year by year, this has also caused a lot of PCB enterprise out of the market because of the price war.

"Big enterprise has large amount of raw materials procurement, have certain bargaining chip. But small enterprise didn't have this kind of bargain ability, we can rise as we want, otherwise, we won't supply. As a result, the downstream small factories’ cost will be increased, increased difficulties of survival, and will accelerate the merger and acquisition, integration, industry reshuffle." A PCB raw material manufacturers’ person in charge ,who said like this, think CCL copper clad and raw materials will continue to rise, as a result, it has a price but no sales, some micro-small and medium-sized pcb factories, who will suffer a greater impact and may have the risk capital chain rupture in 2017.

Since early 2016, PCB standard copper foil prices have risen more than 50%, copper foil processing fee and effective CCL copper clad price has been higher than the original average by above 100% and 50% respectively. In early November 2016, the original copper prices soared to 48000 yuan/ton, due to the original copper prices rose 26%, the impetus of increasing in the price of electrolytic copper foil is transferred from the processing fee to the original price of copper, electrolytic copper foil overall prices have broken through 110000 yuan/ton. According to Taiwan media reports, in January 2017, copper foil processing appeared again a small increase.

A senior boss who has been in PCB industrial for many years said, "copper-clad manufacturing enterprises, change the old payment term that’s to pay after arrival three or five months .Now when we buy the copper foil with cash , copper foil prices rose by 20 to 30%, we still have to line up the order because it’s limited supply." Material sheet transactions generally payment term 90 days to 6 months, after lithium battery copper foil in big demand, some vendors take cash to buy materials, indirect cause prices of vicious competition, this kind of thing has been never happened in the past more than 30 years of PCB circuit board industry.

Copper foil is in short supply in the past year, in March last year,after KB, who has the highest market share & has the deep influence of the largest copper clad companies send the price increase notice, following KB step, other raw material merchants began to rise, stimulate the upstream and downstream supply chain also fully follow up.

Copper foil supply shortage at the same time also drive the other raw materials rise quickly, say industry news CCL another glass fiber cloth material may have to go to 7 yuan/meters, aluminum plate & light guide plate has risen more than about 20% , FR - 4 have risen by more than 40%, plastic board, plastic pieces to rise by more than 10%, even the cartons are in cash transactions.

Difficult expansion, the increase in the price of copper foil, CCL, out of stock , When alleviate?

Copper foil and copper clad and PCB manufacturers long-term struggle in the bottom of supply chain, who never think that lithium battery which used on electric car was born, this round increasing is so rapid and sustained in raw material cycle, this boom is more because electronic copper foil production changed into lithium electricity copper foil production.

According to Japan's electronic circuit industry’s the latest statistics show that in October 2016, the Japanese printed circuit board (PCB;rigid board + flexible board module board) production has fallen to 129.3 square meters in the same month last year , production declines for 11 months in a row, electronic flexible board is plunging nearly 3%. For example, a Japan copper foil company who produced more than 3000 tons of copper foil , now has been basically doesn’t produce electronic copper foil used for domestic market.

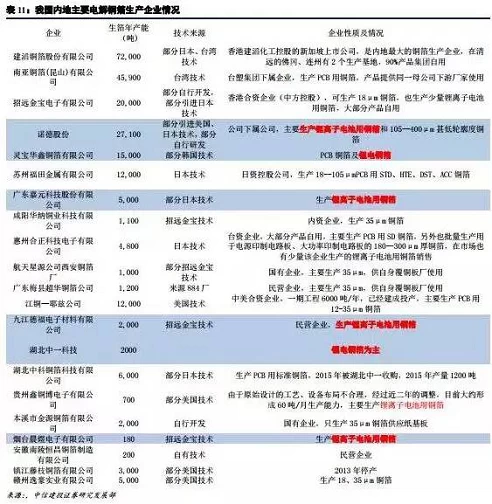

Global electronic copper foil production capacity is 41000 tons per month, which already has more than 8000 tons stopped production. Japanese copper foil companies have closed electronic copper foil production as early as three years ago, switched to high speed board specialized copper foil, high frequency copper foil, encapsulation used of copper foil, flexible board specialized copper foil. On the whole supply chain, there are about 12000 tons of electronic copper foil gone. At present, whether new or old copper foil enterprise, all of their production expansion has surrounded about lithium battery industry.

Due to the electrolytic copper foil ’s new production cycle need 2-3 years, so in the next 1-2 years, the shortage of copper foil used on CCL and PCB will be the normal state. This is mainly due to the production of electrolytic copper foil’s core equipment of titanium cathode roller, monopolized by Japanese companies, production cycle need 3 months, lead time will be more than one yea. At present, titanium cathode roller most orders are supplied to the lithium electricity copper foil factory, which can’t meet the CCL and PCB copper foil companies to increase the production. In addition,according to the different characteristics and production requirement of lithium electric copper foil & CCL, PCB copper foil , CCL and PCB copper foil is easy to transfer use on lithium electricity, vice is difficult to achieve.

3333 Actually, another main material in CCL - electronic glass fiber cloth, over the years ,it has been in a state of unprofitable or loss, which caused some electronic fiberglass company shut down or cut production. Recently learned that many at home and abroad electronic glass fiber cloth enterprises stopped production due to kiln maintenance , and a kiln maintenance cycle is about half a year or so, this marks predict the supply of electronic fiberglass cloth will collapse in the near future, followed by a big rise in price for electronic fiberglass cloth.

3333 Actually, another main material in CCL - electronic glass fiber cloth, over the years ,it has been in a state of unprofitable or loss, which caused some electronic fiberglass company shut down or cut production. Recently learned that many at home and abroad electronic glass fiber cloth enterprises stopped production due to kiln maintenance , and a kiln maintenance cycle is about half a year or so, this marks predict the supply of electronic fiberglass cloth will collapse in the near future, followed by a big rise in price for electronic fiberglass cloth.

According to the market news, since the first quarter of 2017, the PCB industry from upstream equipment factory, raw material factory to downstream manufacturers are present slack-season isn’t slick. One is, electronics car plate board increase the proportion, increased from 0.5 square meters of copper foil substrate to 2 square meters of that; The second ,it’s said that in the second half year, the Apples (iPhone8) will use line width, line spacing smaller "Substrate Like - PCB" (Abb. SLP) technology, it will replace the previous HDI PCB technology.

If considering the CCL, PCB companies generally promote inventory stock up , the supply of copper foil will be more nervous.

It is reported,orders for production equipment to provide lithium electrolytic copper foil for new energy vehicles has arranged to the second half of 2017, estimates the status of the shortage of the copper foil, CCL, PCB manufacturers have to suffer at least a year and a half to two years. Two or three years later, probably due to the lithium battery furious competition of new energy vehicles, some copper foil production enterprises again return to CCL and PCB.

PCB industry is how to break through?

Copper foil prices remain high. Most PCB factories started already after CNY holiday, although the raw material supply situation will be more nervous, but the new energy vehicles production has gone to the off-season, part of the copper foil factory has changed capacity back to PCB copper foil market, there are some PCB factories who prepared in advance, the actual supply is not so nervous.

In fact, the CCL price is only 1/3 of the total price of PCB, the proportion of copper foil price impact on the CCL is far more than that of impact on the PCB, PCB market in long-term vicious competition, large pcb factories’ price increase range isn’t big, but the small and medium-sized enterprise has to rise in price. However, large pcb factories themselves price are far higher than small and medium-sized enterprise and large pcb factories has big MOQ limited.

Most of the small and medium-sized PCB factories don't have enough cash to hoard the PCB raw material, purchasing cycle is very short.Raw material price increase, which cause an increased demand for cash,so capital chain is tension. Because production is not large, the proportion of profit is highly influenced by CCL price. Both let the small and medium-sized PCB factory suffer CCL price increases, so they has to send the price increases notice.

Instead of raw material price rises to destroy part of the manufacturer, which let big factories have more customers, in a same procurement requirements, big factories compared with the similar factories, in the face of upstream suppliers ,who have stronger bargaining power and the right to require delivery date. For customers,cooperate with large factories, who will have to pay a higher price and will be more passive and not flexible on the MOQ issue.

On the one hand, the PCB factories in 2017 when bargaining with the customers, they know now market, may not require products on sale. PCB manufacturers may change the old payment term to new payment term, old is to pay after shipment, new payment term is to pay before shipment.Board out of stock is inevitable, PCB suppliers/factories shold have a long-term plan.

On the other hand,this crazy is not sustainable, copper foil market continued high fever, there are the hype factors.The lithium electricity copper foil demand won’t increase month by month, also won't high-speed expansion. Among PCB factories,they should keep the rational competition, should not blindly follow suit, bidding & stocks & price war again, careful consideration on purchase varieties and quantity,couldn’t disorderly restock.

As the new energy cars, mobile phones, LED small spacing, communication base stations and other major electronics segment market demand, the PCB industry market gradually warming, PCB factories should seize the opportunity, improve their own quality, strives for perfection, improve yield, reduce cost and avoid vicious competition, this is the way to break through.

For copper foil industry, they should make full use of the time price rise to improve product technology and quality, promote technical progress of copper foil. Now into the era of high frequency and high speed material,China PCB factories basically can't make, Taiwan manufacturers can't make either, all of them are specified to make by Japan manufacturers. For copper foil factory doesn’t have profit and no technology investment , so they are no technological progress, this kind of enterprise can't last for a long time. This kind of industry chain is unhealthy, adverse also to our own, and now the copper foil factory, should take the good opportunity to increase investment in research and development, which is undoubtedly helpful for industry.

In the long run, the raw material price increase will speed up out the micro, small and medium enterprises who are not competitive, which will enable industry return to rational range, conducive to the healthy development of the industrial chain.