The Challenges of Panelizing PCBs

o-leading.com

o-leading.com

2018-01-08 14:20:40

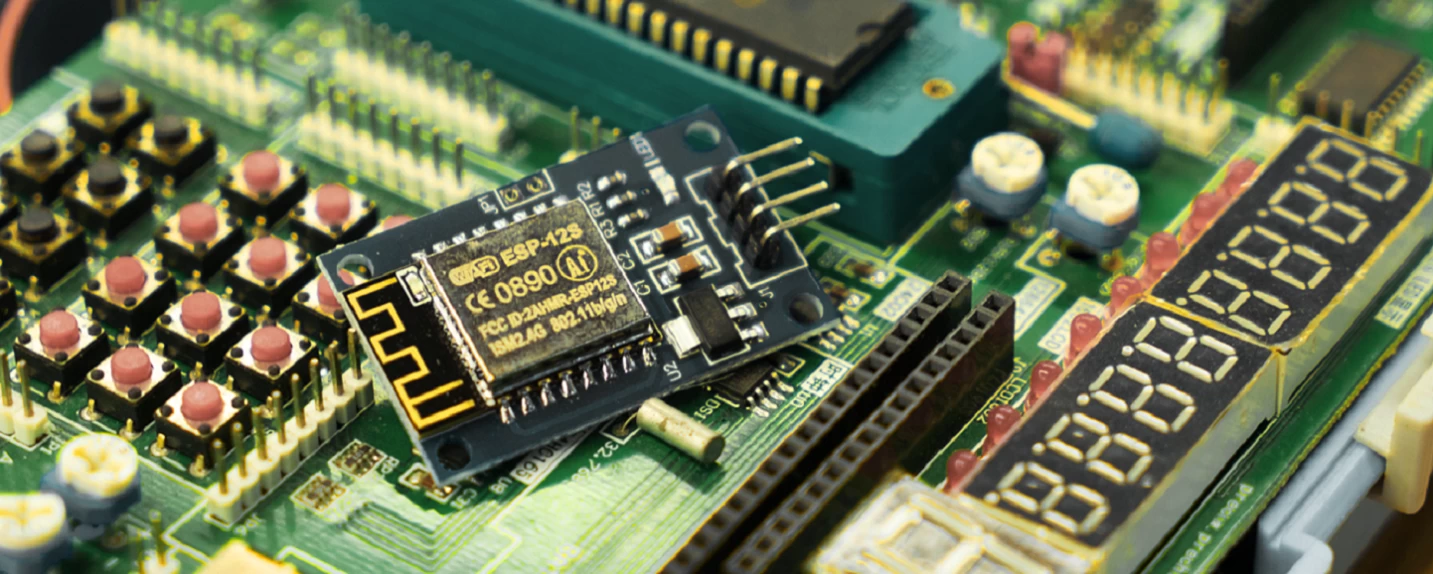

Printed circuit boards (PCBs) need to be kept secure during the manufacturing, shipping, and assembly processes to avoid damaging the unit.

Panelizing PCBs is a way to safeguard their integrity.

In addition, panelization allows China pcb manufacturers to assemble multiple boards simultaneously, reducing costs and production time. Panelization must be done properly so that PCBs will not be broken or otherwise damaged during separation.

Challenges:

Panelization presents a number of challenges in several areas:

1.Depanelization– disadvantages of some depanelization methods:

Using a router could require additional cleaning prior to shipment. This method produces a lot of dust which must be vacuumed out.

Saws can only cut in straight lines, so are appropriate only for certain arrays.

Lasers should be used only with an optimal board thickness of 1 mm or less.

2.Overhanging parts– require pre-routing to avoid interference with depanelization:

Components overhanging an edge can fall into adjacent parts.

Overhanging components can be damaged by a saw blade or router during depaneling.

3.Incomplete data files– sometimes incomplete files are provided to the Printed circuit board manufacturer, which can increase costs in several ways:

“Breakaway holes” or “mouse bites”– These tiny holes permit small PCBs to be used in an array. Drilling these holes leaves rough edges. If the mouse bites are not shown in the data file, the unexpected extra work to remove the edges increases labor costs.

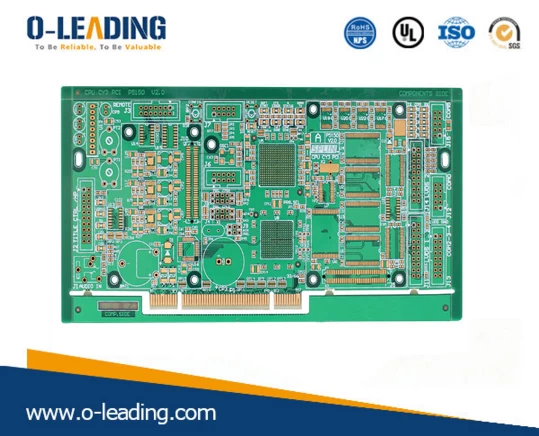

Taking the above challenges into consideration, an experienced PCB manufacturer can avoid problems before they occur.Working with a preeminent printed circuit board supplier like O-Leading will ensure that your panelized PCB works as it should, is cost effective, and meets the highest industry standards.

Challenges:

Panelization presents a number of challenges in several areas:

1.Depanelization– disadvantages of some depanelization methods:

Using a router could require additional cleaning prior to shipment. This method produces a lot of dust which must be vacuumed out.

Saws can only cut in straight lines, so are appropriate only for certain arrays.

Lasers should be used only with an optimal board thickness of 1 mm or less.

2.Overhanging parts– require pre-routing to avoid interference with depanelization:

Components overhanging an edge can fall into adjacent parts.

Overhanging components can be damaged by a saw blade or router during depaneling.

3.Incomplete data files– sometimes incomplete files are provided to the Printed circuit board manufacturer, which can increase costs in several ways:

“Breakaway holes” or “mouse bites”– These tiny holes permit small PCBs to be used in an array. Drilling these holes leaves rough edges. If the mouse bites are not shown in the data file, the unexpected extra work to remove the edges increases labor costs.

Cumulative and registration tolerances– If tight tolerances are not specified in the data file, the cumulative effect of tiny variances could cause failure. With more boards in the array, registration can go off-center.

Difficulty troubleshooting problems– Without complete data, issues such as a short during power ground short testing can be extremely difficult to trace back to their source.

Taking the above challenges into consideration, an experienced PCB manufacturer can avoid problems before they occur.Working with a preeminent printed circuit board supplier like O-Leading will ensure that your panelized PCB works as it should, is cost effective, and meets the highest industry standards.