Printed Circuit Boards Assembly Methods

o-leading.com

o-leading.com

2017-06-26 15:58:10

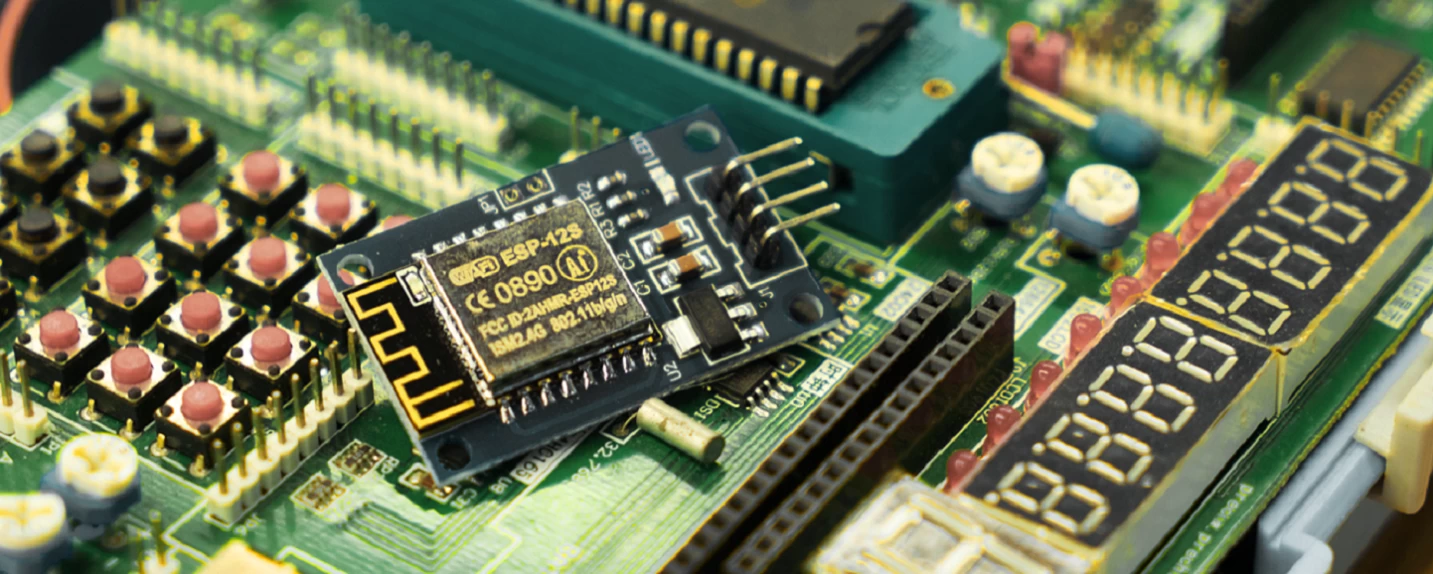

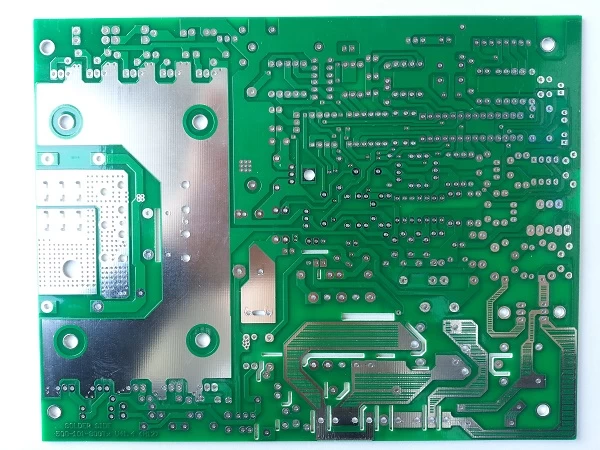

A PCB offers mechanical support and connects electronic components electrically using conductive tracks and several other features etched from copper sheets illuminated onto non-conductive substrates. PCBs are assembly and design defines the type of final PCB product; that is, single sided PCB, double sided PCB or multilayer PCB. Modern PCB assembly processes are extremely complex and automated thus high speed which might lead to component failures. This is due to lack of sufficient understanding of the concept of design for assembly (DFA). Manufacturing and assembly should be considered during the design stage of every PCB. We will discuss the PCB assembly methods in this article.

Some of the important components needed for PCB assembly are: High Quality PCBs china, Electronic components, Soldering materials-solder wire, paste and solder bar, Soldering flux, Soldering equipment like soldering station and SMT equipment.

Before assembling the PCB, you must first contact the assembly company to discuss your project with them. Communication is essential in the performance of the contract, both parties should participate. In addition, before submitting the PCB for assembly, some tools can be provided to the PCB assembler. These items include the BOM (BOM), which should specify the part number, description, reference, value, package type and number. Always make sure this information is accurate and contains every detail you want to include in the PCB to avoid assembling PCBs that do not meet the specifications.

PCB assembly with thru-hole electronic components

Electronic components with leads coming out inserted through tiny holes in a PCB for soldering are known as thru-hole electronic components. The assembly process for these components when used in PCBs requires the use of hand soldering and wave soldering. Moreover, the temperature range used in this process depends on the solder type used. In these soldering processes, the solder is usually in the form of solder bar and it is put in a high-temperature bath. Moreover, the PCB with all its thru-hole components in holes is the passed over the molten solder using a conveyor belt. The soldering process involves the following procedures: inserting the electronic components in the molten solder, flux application, cleaning and testing. However, sometimes hand soldering is carried out in assembling companies with less with little work load or in repair work. However, a quality soldering station or solder wires and flux are use in this process.

Electronic components with leads coming out inserted through tiny holes in a PCB for soldering are known as thru-hole electronic components. The assembly process for these components when used in PCBs requires the use of hand soldering and wave soldering. Moreover, the temperature range used in this process depends on the solder type used. In these soldering processes, the solder is usually in the form of solder bar and it is put in a high-temperature bath. Moreover, the PCB with all its thru-hole components in holes is the passed over the molten solder using a conveyor belt. The soldering process involves the following procedures: inserting the electronic components in the molten solder, flux application, cleaning and testing. However, sometimes hand soldering is carried out in assembling companies with less with little work load or in repair work. However, a quality soldering station or solder wires and flux are use in this process.

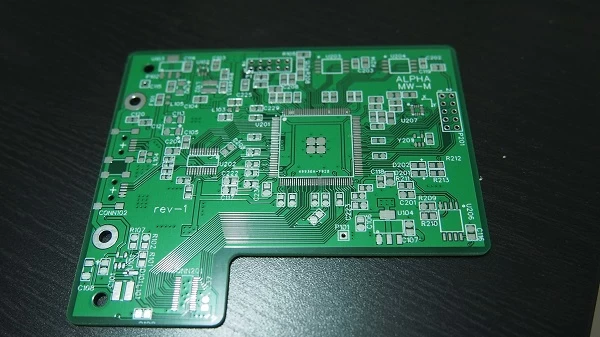

PCB assembly using Surface Mount Technology

The SMT (Surface Mount Technology) is a PCB assembly process for SMD electronic components. Unlike thru-hole components, SMDs don’t have legs or leads but they are instead mounted on the surface of a PCB. The electronic components and soldering materials used in this process are also different from those used in the thru-hole soldering process.Surface mount parts are held in place by the tension of the solder paste which is allowed to be flow continuously. This is in a bid to prepare them for the process of wave soldering. On the other hand, as the pieces are placed on the PCB, there is a literal push as the pick and place inserts them in the board. The downward pressure acting on the board can cause board flex in panels with bare minimum connecting tabs between the boards. As the pick and place moves away, the board snaps to its original position and sometimes this might flick pieces off the board.

The SMT (Surface Mount Technology) is a PCB assembly process for SMD electronic components. Unlike thru-hole components, SMDs don’t have legs or leads but they are instead mounted on the surface of a PCB. The electronic components and soldering materials used in this process are also different from those used in the thru-hole soldering process.Surface mount parts are held in place by the tension of the solder paste which is allowed to be flow continuously. This is in a bid to prepare them for the process of wave soldering. On the other hand, as the pieces are placed on the PCB, there is a literal push as the pick and place inserts them in the board. The downward pressure acting on the board can cause board flex in panels with bare minimum connecting tabs between the boards. As the pick and place moves away, the board snaps to its original position and sometimes this might flick pieces off the board.